Supplier Selection & Qualification

The COVID-19 Pandemic has revealed outdated supply chain processes and the vulnerability of manufacturing/service businesses worldwide. The main trends of this effect include 1) Price fluctuation, long lead times, and delays negatively affecting the relationship between suppliers and customers and 2) Single or limited qualified suppliers and a lack of risk planning due to underestimating the possibility of severe disruptions. The effect of the pandemic fundamentally made businesses rethink their supply chains. Due to this, the existing supplier qualification process has moved from a “behind-the-scenes” purchasing responsibility to being a prime driver of business.

Keeping the above situations in mind, a new supplier qualification process with multiple-stage gates is designed to help companies qualify prospective suppliers who can be trustworthy partners during disruptions/uncertainties. Depending on the size of the companies and the team's maturity, the new supplier qualification process is flexible to use either as part of a project or just as a standalone process. Also, the process is designed with a built-in risk mitigation plan during companies’ day-to-day operations and disruptions/uncertainties.

STAGES

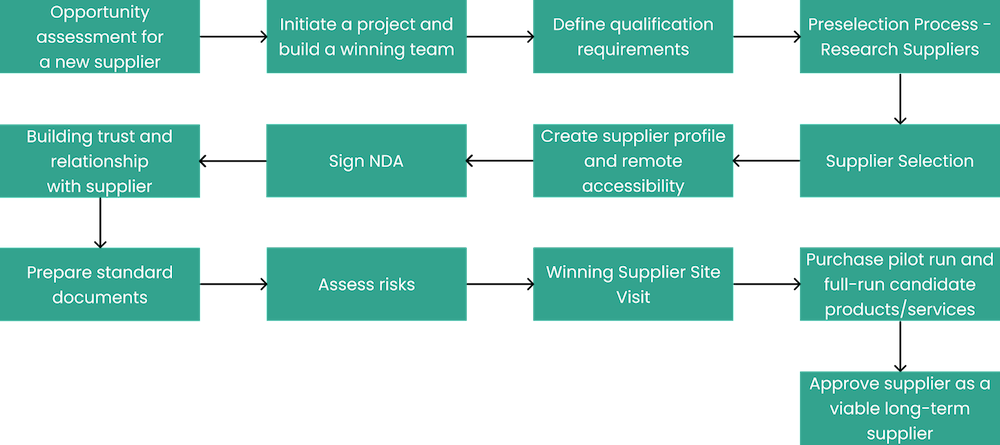

The following consolidated stages and their objectives are described in the blueprint:

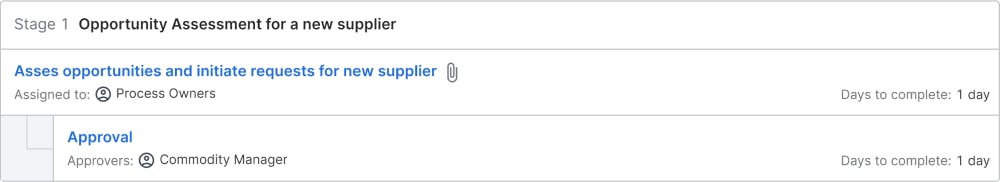

Opportunity Assessment for a new supplier

Critical to define the goal and what it is trying to achieve, including objectives, scope, and necessary resources.

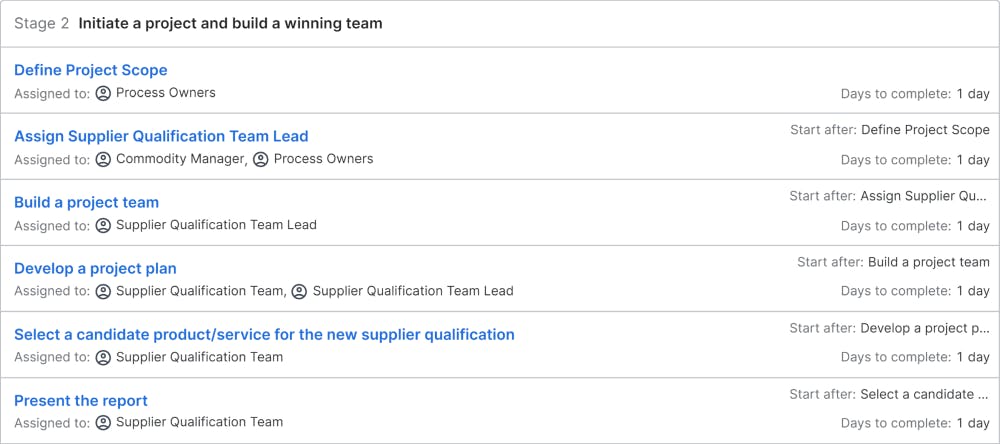

Initiate a project and build a winning team

Identify and organize the team involved in the decision-making and development process and any stakeholders.

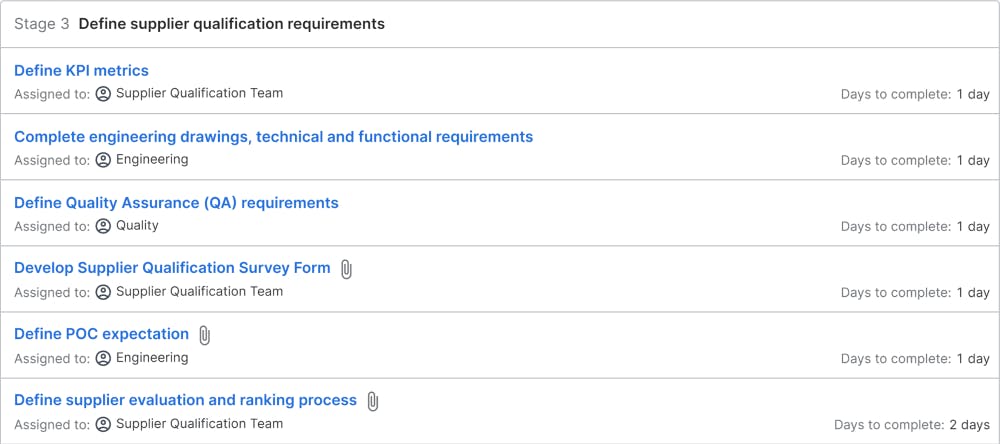

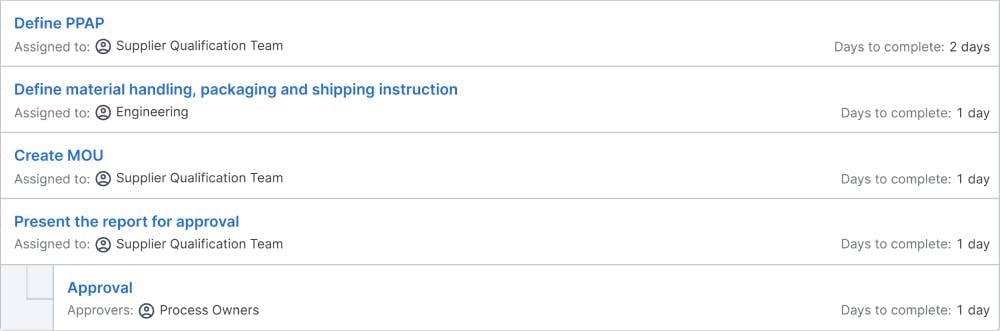

Define supplier qualification requirements

Price, quality, challenges, functional requirements, nonfunctional requirements, service provisioning

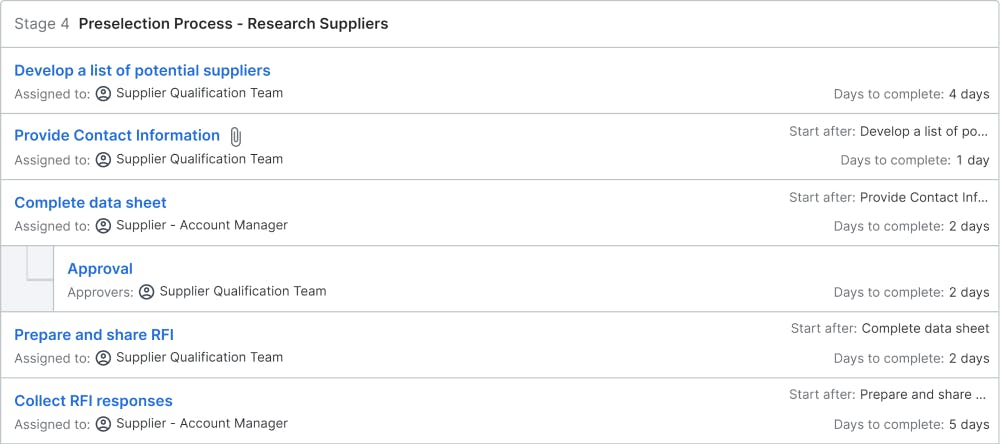

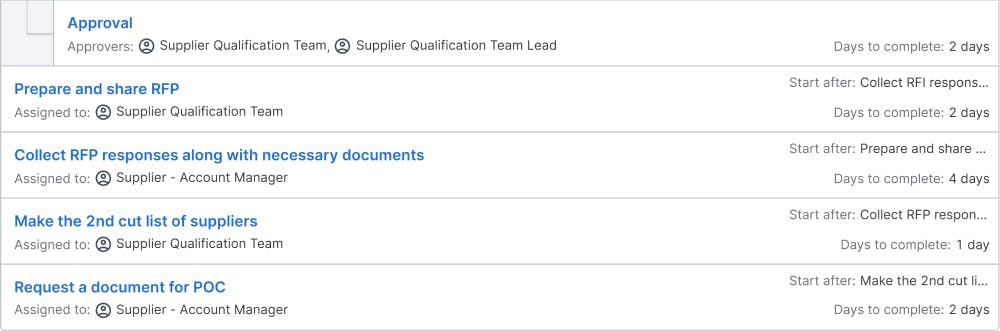

Supplier Research and Profile Development

Gain detailed knowledge of suppliers’ industry, find suppliers, industry leaders, innovative companies, philosophy and strategy match between supplier & Company, who best meets your needs, the basis for a site visit, information for use in developing negotiable issues

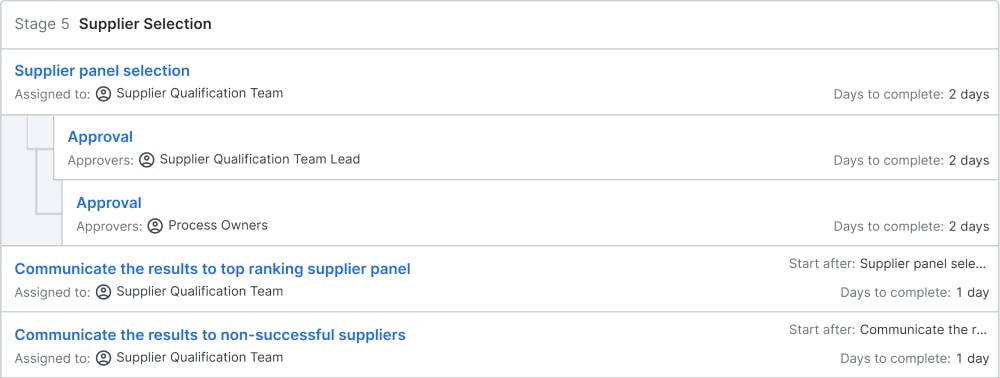

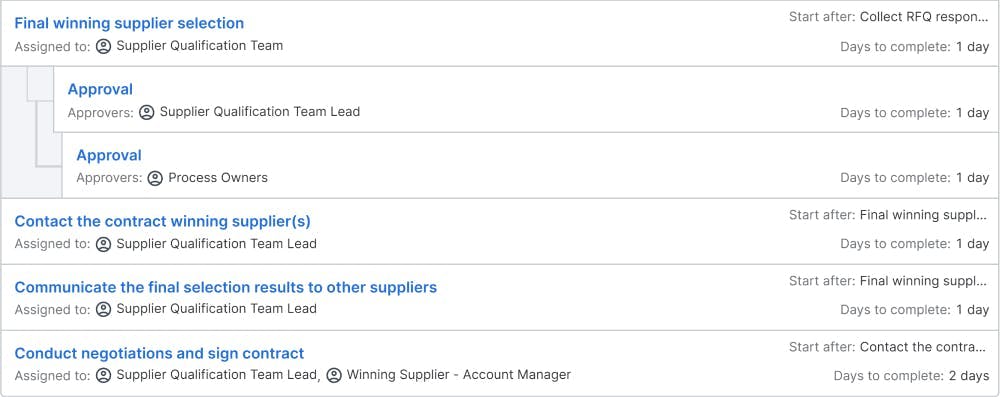

Supplier Selection

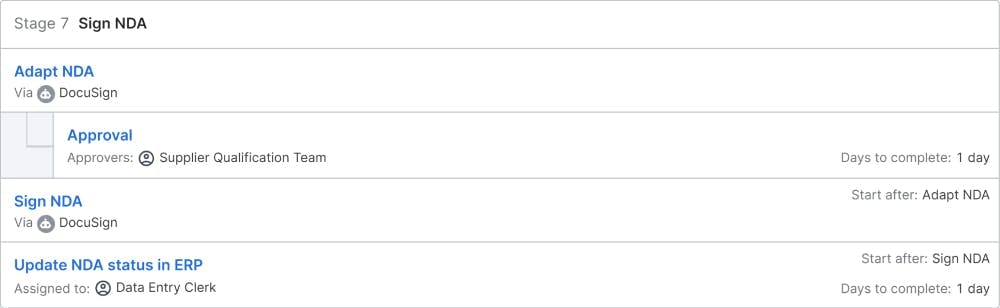

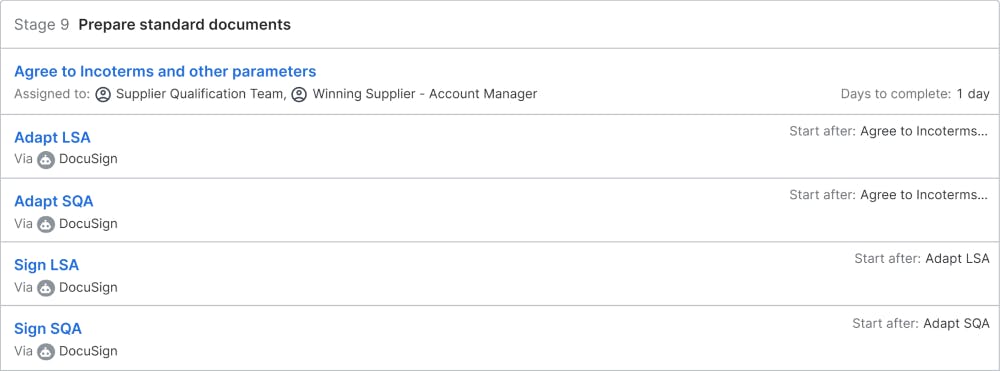

Site Visits, Presentation, Negotiation, signing NDA / Contract

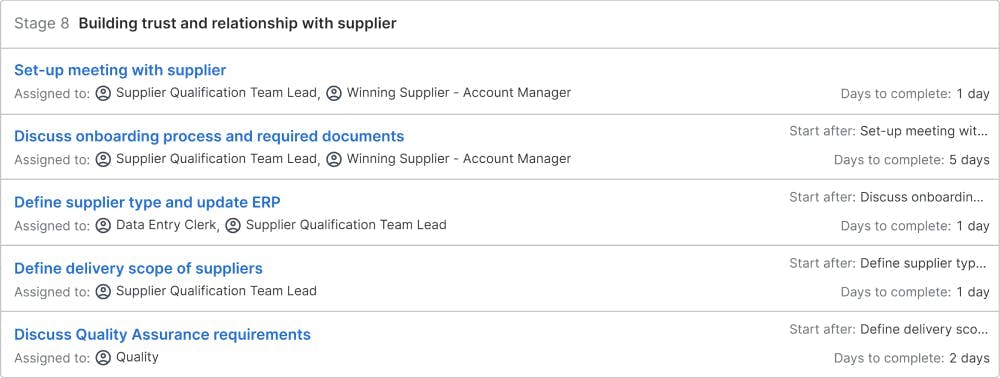

Build trust and relationship building

This is the most important for continued success particularly for better underestimating during severe disruptions/uncertainties.

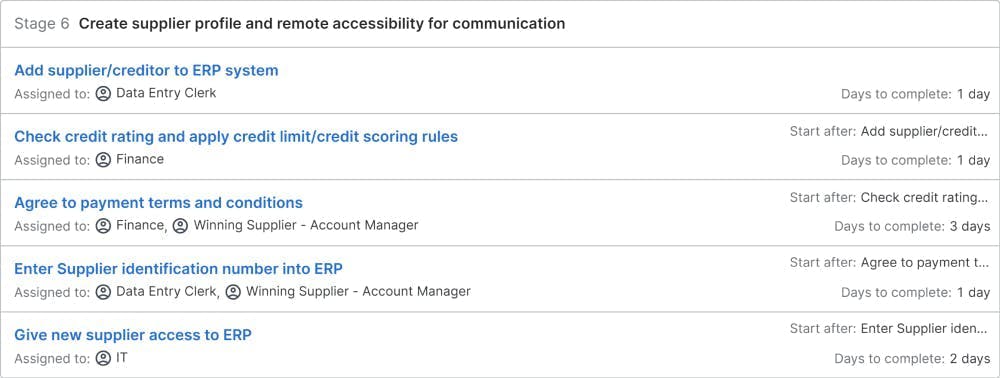

Create a supplier database

System for digital communication

Risk Assessment

The supplier qualification process itself is called a risk-based supplier qualification program.

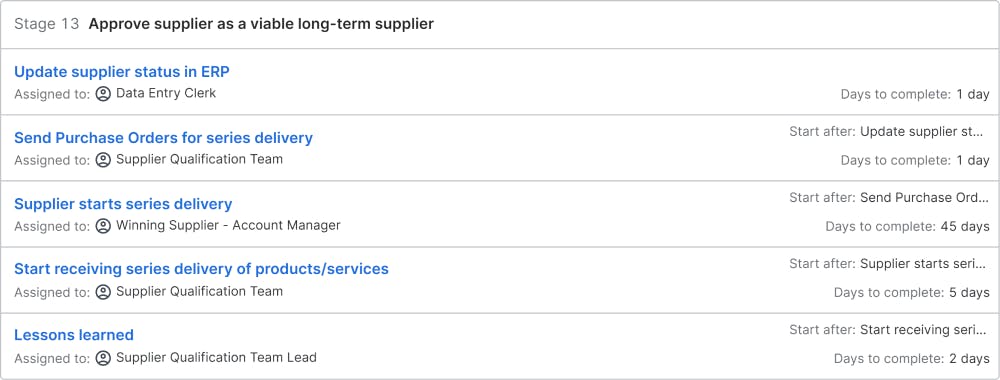

Process implementation

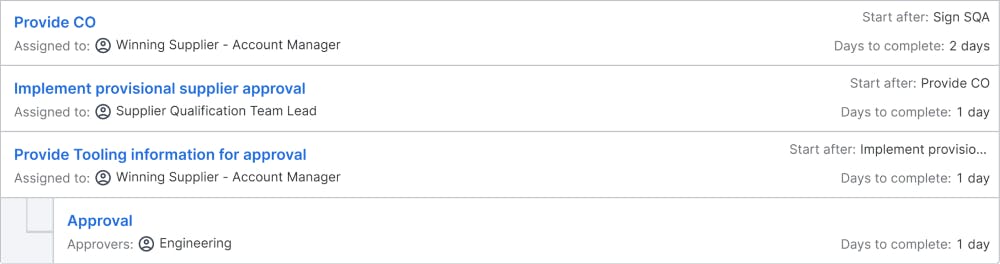

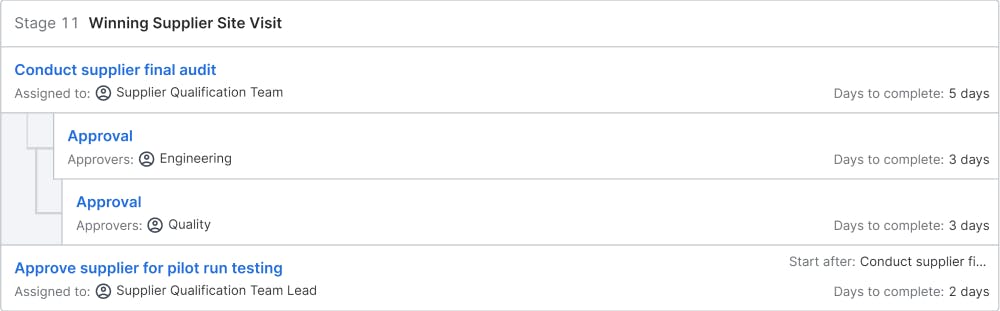

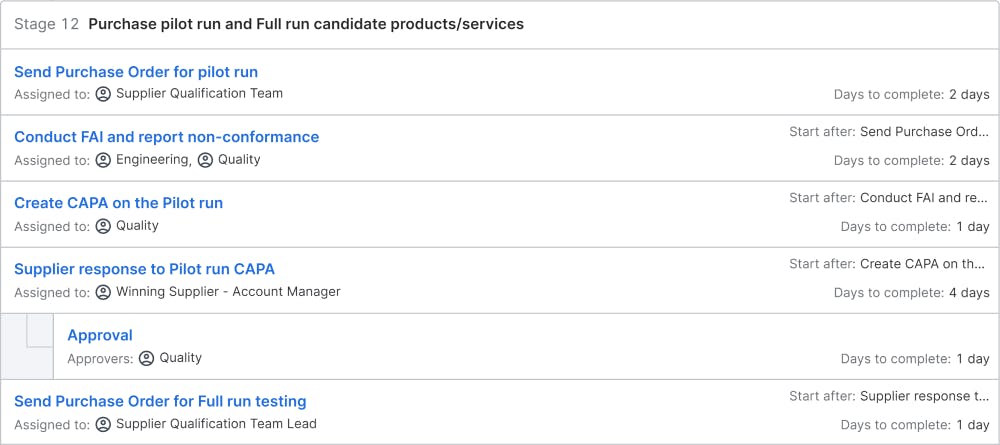

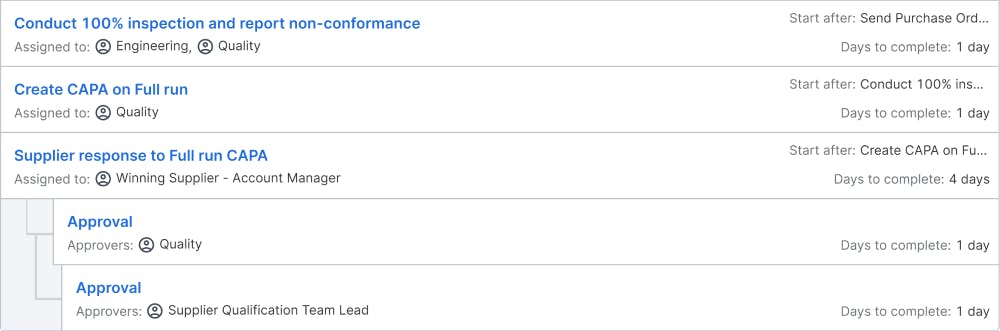

Send PO for a pilot run/full run testing and approval. Gather and evaluate test results with the team and stakeholders to compare outcomes and see if they meet the defined success criteria.

Performance monitoring and continuous improvement

Lessons learned and corrective actions.

WHY USE THIS PROCESS

Importance of using the process and any specific value add (data collection, details that are often forgotten, etc). Who will run and manage this workflow?

New Supplier Qualification Process is based on Good Supply Chain practices involving a cross-functional team headed by a team leader. Process Owners identify the need for a new supplier. They define project scope statements that align with business goals, KPIs, and stakeholders’ expectations in consultation with the Sourcing Leader / Commodity Manager. The document with scope statements gives the project a framework for success. In addition, the scope document provides project objectives, schedules, tasks, and deliverables. Process Owners, along with the Sourcing Leader / Commodity Manager define a Supplier Qualification Team and a leader who has project management skills. The Supplier Qualification Team is a cross-functional team consisting of members from purchasing, operations, finance, engineering, and quality departments. The team leader will run and manage the workflow.

As organizations grow and evolve, their manufacturing/service needs will shift. Supplier development is essential because it ensures that the suppliers will evolve with their customers. We don’t want to outgrow suppliers or manufacturers and be forced to find a replacement. Investing in supplier development will foster fruitful business relationships and ensure that companies’ products or services improve in quality. Some of the advantages of supplier qualification and development are as follows:

A shorter lead time improves on-time delivery schedule

Product Safety and Quality improvements

Cost savings

Efficient and Good Supply Chain Practices

The improved business relationship between the Company and the supplier

Support company lean practices and continuous improvement process

It is important to have a standard process to assess suppliers fairly and meet delivery requirements. As sourcing is often time-critical, having a standard process in place improves speed of onboarding and reduces effort for all parties involved.

WHO SHOULD USE THIS PROCESS

The new supplier qualification process template is a good choice for Multinational/global businesses and in-house manufacturing companies. The size will be medium and large-size, with annual revenue above $500 million to $1 billion, having employees above 500. The New Supplier Qualification Process aims to ensure all interests across multiple departments of any organization are addressed. The process is designed as a generic version covering various aspects. Depending on the size of the companies, it's flexible to use as part of project-based or just as a standalone process. We recommended all steps to set up the process.

Depending on the size of the companies and the team's maturity, steps could be removed or skipped. The new supplier qualification process can also be customized for small companies with annual revenue of less than $500 million. Once the process is set up in an organization, it can be used for qualifying future suppliers or continuous improvement and development of existing suppliers.