Packaging Development

Packaging is critical to all consumer goods and often has an entirely separate set of lead times and requirements from the products contained within. As such, this process is designed to be run in conjunction with but separate from a standard NPI process, and aligned to deliver samples as per the build requirements in a consumer electronics NPI process.

STAGES

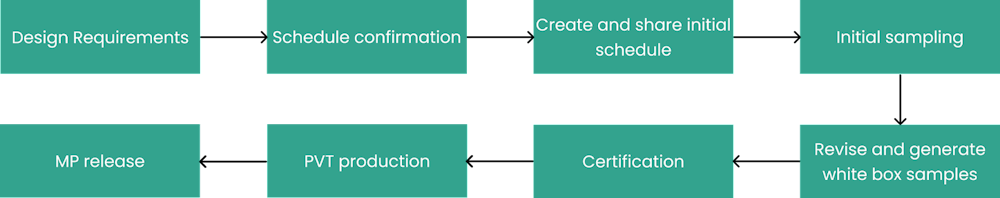

The following stages are identified in the blueprint:

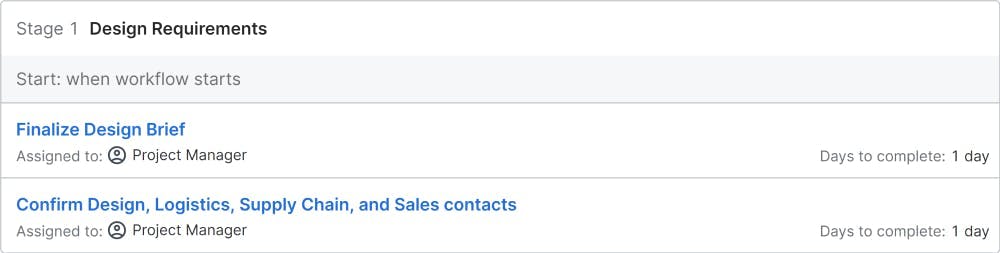

Design Requirements

The process starts by gathering design requirements from the Sales and Marketing teams. Often these requirements exist before the packaging development process begins for the supply chain team. They can thus be requested directly from the Marketing department in the first stage. As with any process, the specifics require confirmation, and the Supply chain lead is advised to follow the approval process to confirm that key details such as shelf size, master carton quantities, and compliance labeling have been correctly called out in the Design documents. For example, final labeling, sealing, and size requirements will differ depending on the product, manufacturing location, and sales regions.

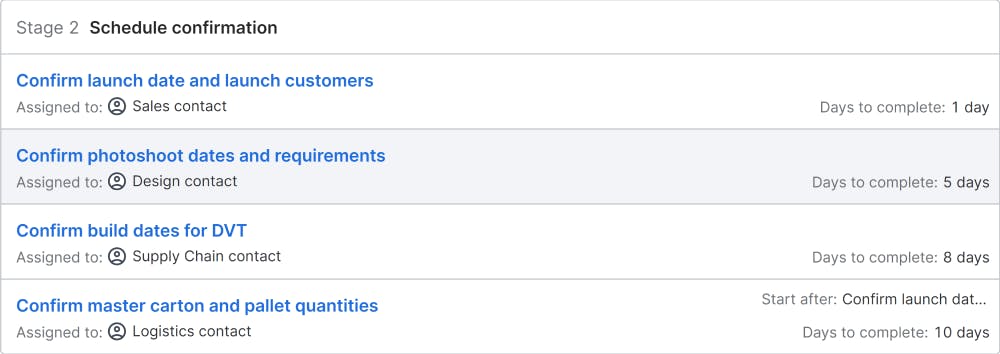

Schedule confirmation

This stage outlines the necessary interactions with Logistics, Sales, and Design as per the prior stage and connects Supply chain to the same. Consider this a part of an S&OP process, where the Project Manager (often in Marketing, but occasionally in Supply Chain) gathers delivery dates and quantities for interim steps in the packaging design process such as DVT builds, photoshoots, and shelf samples for retailers. Having these elements in hand greatly reduces future problems.

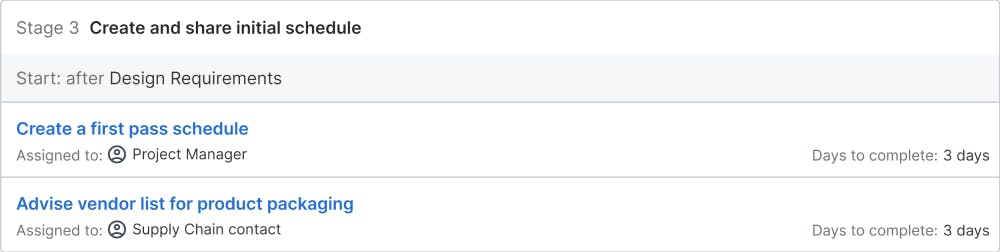

Outline schedule and share

Having sourced scheduling requirements, generate the first pass schedule and share. At this point, there will be limited working prototypes, and the Project Manager may need to gather materials for Supply Chain to start the sizing and material selection process. Also in this stage, the Project Manager works with Supply Chain to confirm, if possible, the vendors for future communication.

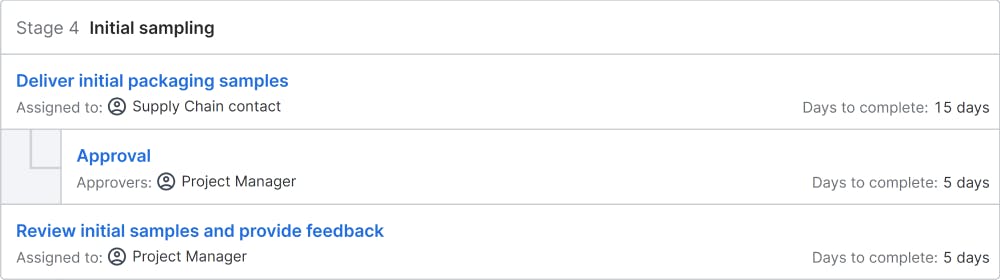

Initial sampling

Once vendors, schedules, and needs are clear, the Supply Chain team should work with nominated suppliers to source initial samples. These often include hand-made brown box samples, quick printed art mockups for exterior visuals, and looks-like/feels-like samples for interior structures such as vacuum-formed plastic or pulp trays. Samples should be reviewed in a larger project meeting before the next stage. This creates the first true gate in the packaging design process.

White box samples

Often used for DVT, white box samples are built to pass drop testing and should be usable in photo shoots as the basis for photoshopped artwork to create marketing materials. The schedule should be at the latest aligned with DVT, but if possible run an additional round prior to DVT dates. Approvals and conversations with suppliers have been fully handed over to Supply Chain at this point.

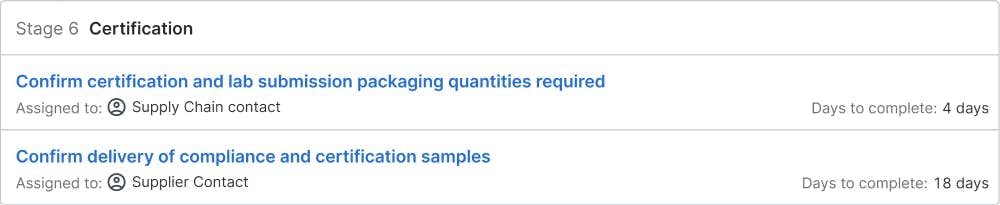

Certification

In this stage finished samples are used to package DVT units for compliance and certification submissions. These samples must be bagged, labeled, sealed, and contain instructions and printed artwork as per final requirements.

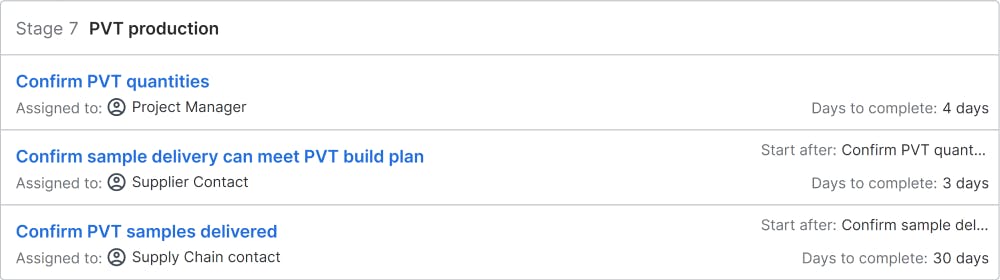

PVT production

In this stage, finished packaging is delivered to the final assembly location to facilitate a complete build for PVT. The packaging should be essentially complete, with print, art, and materials all locked. Changes in this stage should be based on compliance needs only, or failed test results (excessive visual damage on drop tests, for example, or the addition of desiccant for sea shipments).

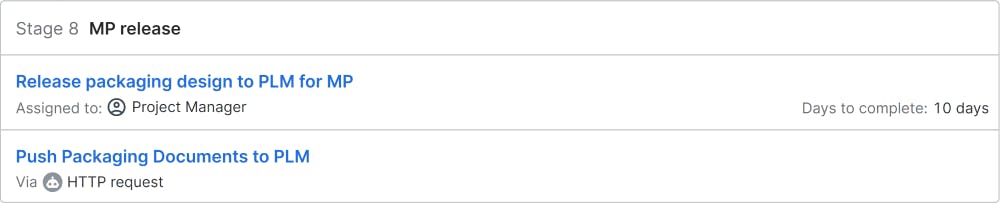

MP release

The project is complete, and further revisions will come in the form of an ECO.

WHO SHOULD USE THIS PROCESS

This process pre-supposes a marketing department and global distribution, so is designed for mid-sized companies. Smaller organizations can make use of it by skipping the global steps that are not required and consolidating the roles to fit their team. While the examples are based on a consumer electronics product’s timeline, the packaging production and design requirements will fit most consumer goods as well.

WHY USE THIS PROCESS

Because it’s not always done in conjunction with the product development process, packaging has an unfortunate habit of being the last piece of the production puzzle and can cause delays or costly reprints if not organized carefully. Using a process with clear steps and deliverables provides the structure to reduce some of these errors and the visibility to avoid out of sync delays.

By putting the packaging design process into a repeatable template, the likelihood of cost overruns or ship date slips decreases, giving the company a more reliable, predictable time to market for new products.