Nearshoring

The process is designed for small to large-size companies to assist with manufacturing relocation from a current supplier closer to its home country and/or closer to the end customer. This process is meant for the customer (product owner) and selected supplier(s) to work together through the Near-Shoring completion. Since most activities will require the new supplier(s) to drive closure, the customer will need to ensure transfer of product knowledge, business requirements and other selected tasks.

STAGES

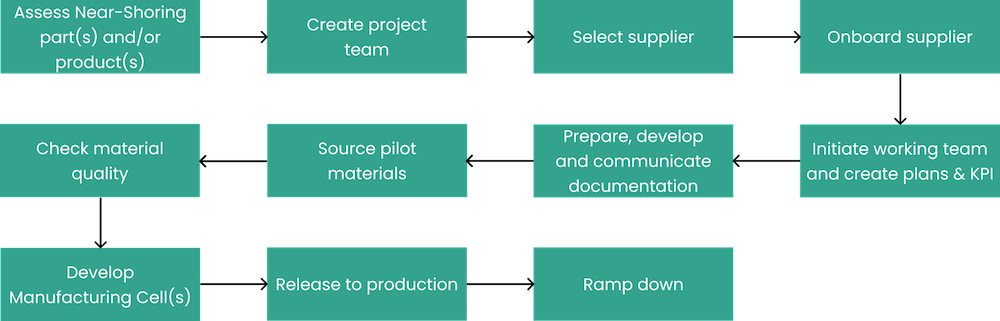

The following stages are identified in the blueprint:

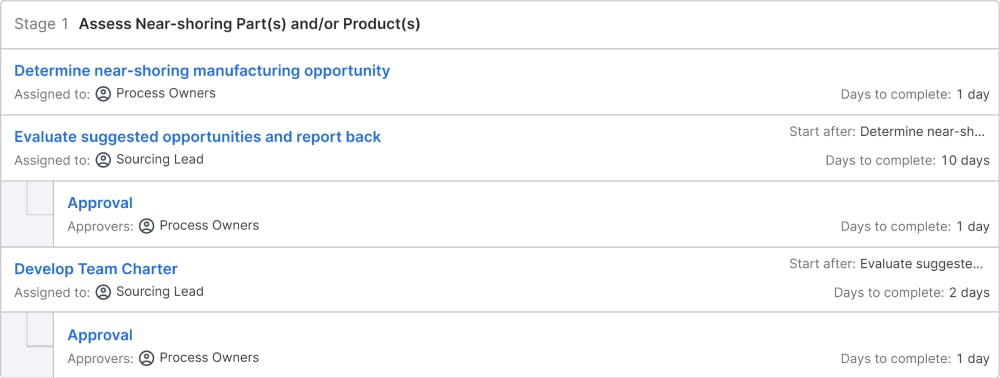

Assessment of Near-Shoring part(s) and/or product

Process Owners initiate the need to Near-Shore the manufacturing of selected parts and/or products based with some guidelines on location and budget constraints to the Sourcing Leader. The Sourcing Leader with a cross-functional team selected to develop potential opportunities of Near-Shoring selected part(s) and/or product(s) for Process Owners’ approval.

Create Project Team

After project approval the Process Owners kickoff a Near-Shoring cross-functional Project Team who creates the top-level project plan and gets approval from Process Owners of approach. At this stage the Sourcing Leader or Commodity Manager would take the lead.

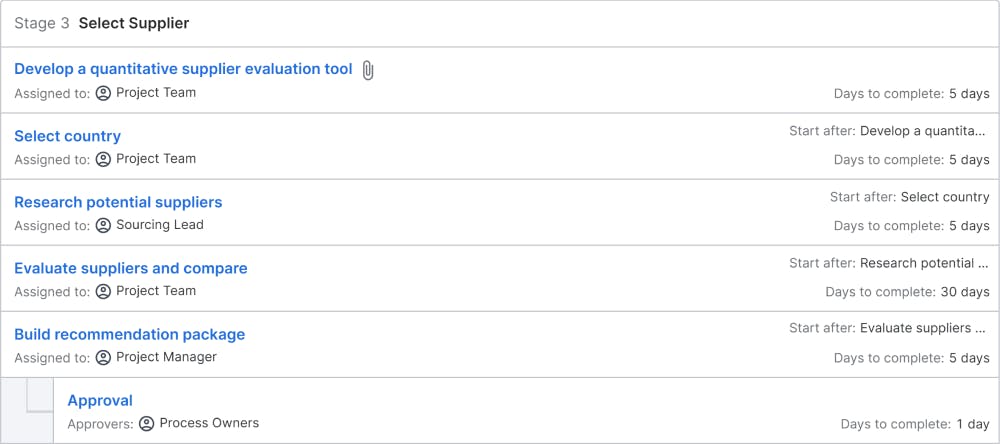

Supplier Selection

The Project Team works together to create supplier evaluation tools that help to select suppliers that could potentially manufacture their product and that have the culture of growing as requirements change.

The Project Team would start building pros and cons of recommended country(s) and suppliers to create a supplier contact list to begin initial supplier discussions based on company policy; an official NDA (Non-Disclosure Agreement) may require approval before detailed discussion can happen.

Project Team to perform supplier visitations and completing ratings within the supplier evaluation tool. After supplier visitations the findings are consolidated and discussed with the whole Project Team to select first and second choice.

Project Team outlines to the Process Owners any restrictions/advantages of doing business/manufacturing within selected country(s), recommended supplier(s), effort/timing/funding required to complete this Near-Shore transfer including language barriers, plus risks/concerns with transferring from current supplier.

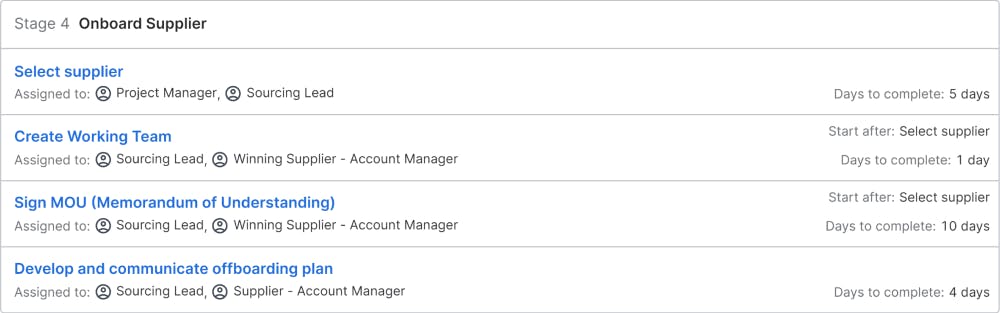

Communication

Process Team develops and communicates to selected suppliers and starts building a cross-functional Working Team reporting to a Project Team. And the MOU (Memorandum of Understanding) gets approved by both parties and starts outlining the MSA (Master Supplier Agreement). The current supplier communication is developed and timing of discussion with the current supplier SMT (Senior Management Team).

Initiate Working Team and Create Plans & KPIs

Project manager communicates with Working Team and discusses project objectives, team structure, timing, etc. to clearly develop a detailed project plan and KPIs (Key Process Indicators) that will monitor progress of the Near-Shoring project. Additionally, it’s recommended to modify the Regrello’s Near-Shoring Workflow to ensure touch points within your project are addressed. This stage will require a project manager or someone that possesses the capability to structure a detailed plan. Ensure Team celebrations after key milestones are achieved. (Project Managers supported by Project Team and Process Owner).

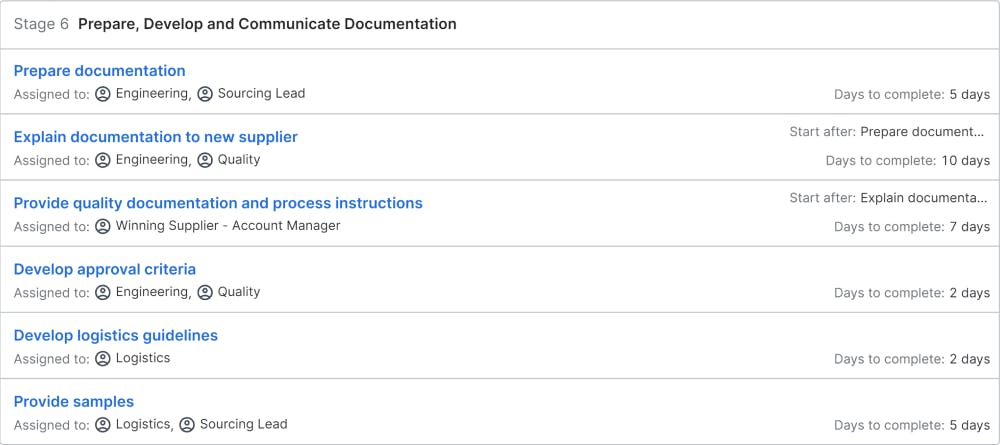

Prepare & Develop and Communicate Documentation

At this stage selected team members will gather/create pertinent part(s) and/or product data, such as BOMs (Bill of Materials), drawings, specifications, process instructions (if available) , special tooling requirements and product acceptance criteria and test plans. In addition, Logistic will develop and communicate guidelines on materials handled from raw material through deliverables including packaging. (Sourcing, Process Engineering, Quality Engineering, and Engineering)

The team has focused discussions of all supplied documentation (listed in 6a) so that the new supplier gains detailed knowledge of requirements for transiting into production at their facility or sub-tier suppliers.

Process instructions are created and validated using a controlled build exercise. (Process Engineering)

When the supplier cannot manufacture directly supplied documentation, such as material substitutions, design changes and others, the technical team member creates a method of communication for such requests to drive customer reviews and approvals where applicable. (Customer Engineering)

For complex parts and/or assemblies the customer provides samples as visual aids to support activities like process development in preparation for controlled builds to provide operator training and validate process instructions. (Process Engineering)

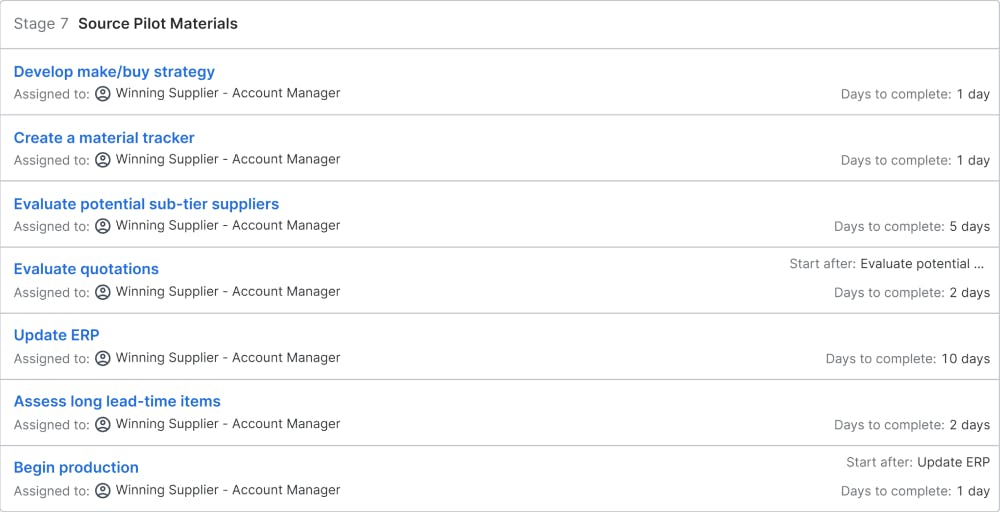

Pilot Materials

The supplier creates and communicates the make/buy strategy and starts releasing RFQ (Request for Quotations) to sub-tier suppliers while releasing internal manufacturing to meet a pilot run. Then follow-ups with releasing pilot material requirements to sub-tier suppliers. (Sourcing)

The supplier’s ERP (Enterprise Resource Planning) systems are loaded with required data to run a costed BOM and it could drive MRP (Material Requirements Planning).

Long-lead items are released, and a material tracking is created that monitors supplier/pricing/ordering/lead-time/receipt, and IQC (Incoming Quality Control) status. (Sourcing and Quality)

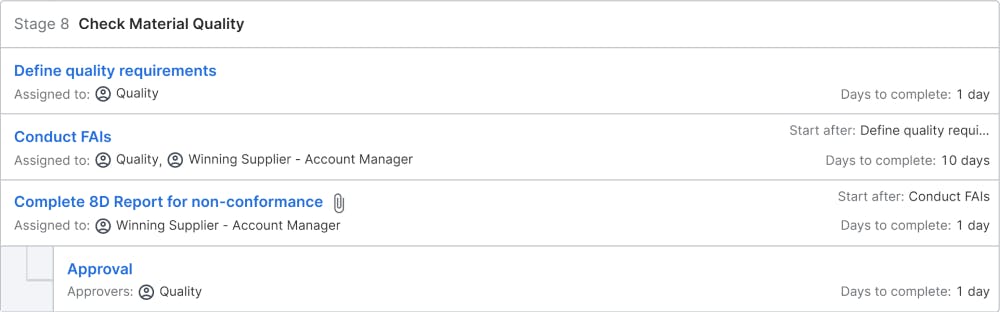

Pilot Materials

Quality provides all quality requirements by part/assembly including any special process inspections and over-inspection (inspection audits) requirements. As material is being received FAI (First Article Inspections) are performed reporting any non-conformances. At this stage 8D reports are issued for non-conformances materials and decisions are made whether to use-as-is or replace. (Quality Engineering)

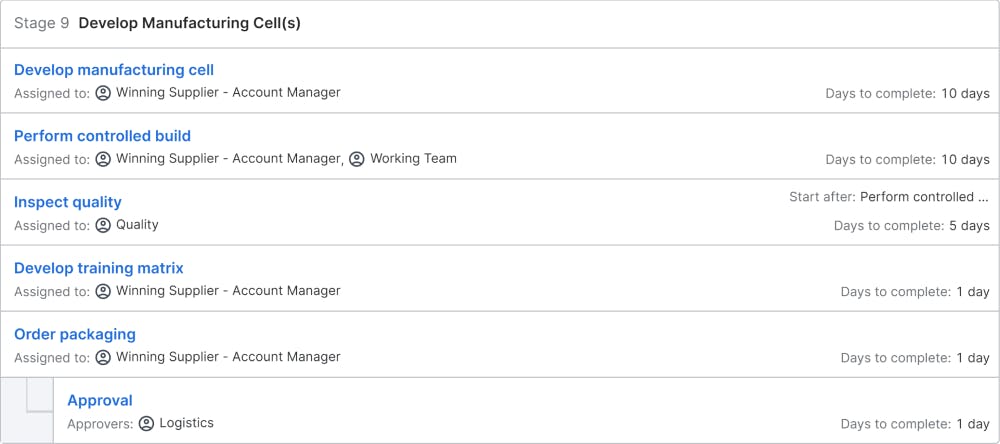

Develop Manufacturing Cells

Supplier develops the manufacturing cells and begins to stage, material, tooling and perform controlled builds to validate process/quality instructions and operator training. After the controlled build the Customer’s Quality Team performs an over-inspection to validate acceptance. (Process Engineering and Quality Engineering)

The Operator Training matrix including cross training is developed, maintained, and proudly displayed within the manufacturing cell. (Cell Management)

Ensure all packaging is ordered and starts prove-out of conformance. (Sourcing)

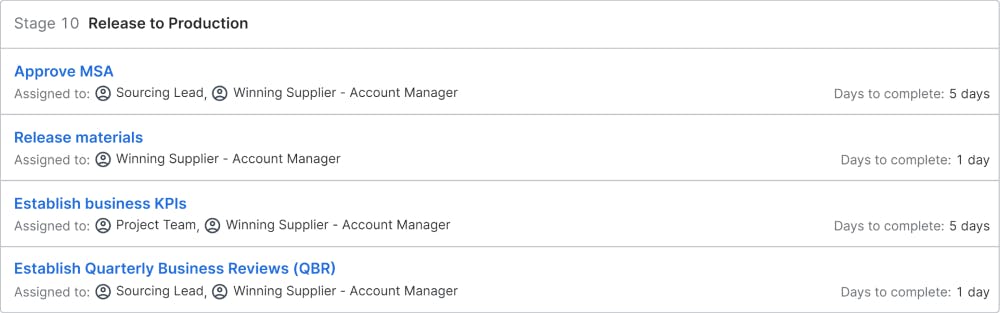

Production Release (Commodity Managers)

The MSA is completed and approved by both parties, then material is released through MRP to achieve the production ramp-up

Production KPIs are established for monitoring supplier’s performance as related to Quality, Delivery, Cost, and Process Improvement.

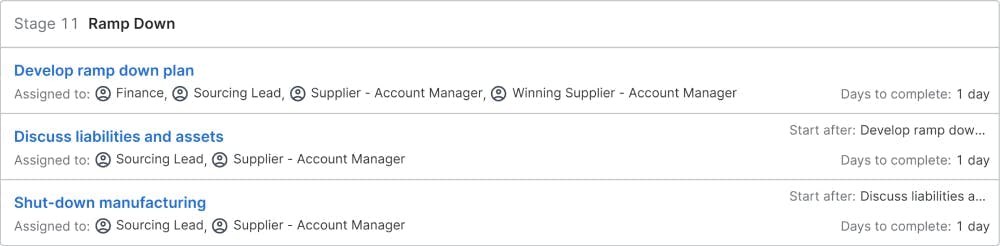

Ramp Down

Develop the ramp-down plan in unison with the new supplier’s ramp-up with a planned overlap to protect customer deliveries. (Commodity Managers)

Customer and current supplier (Commodity Managers) negotiate on how best to handle excess material and customer assets, then current supplier production is shut down…

WHY USE THIS PROCESS

This Near-Shoring Workflow is used to assist with establishing a new supply-base near the company’s home country and/or customer base. Typically managed by the Commodity Manager with the assistance of a focused team, this workflow provides an experienced guide of Near-Shoring touchpoints. These touchpoints ensure the focused team builds a personalized project plan that meets transfer expectations. The workflow supports the transfer of a single part up to and including complete products with thousands of parts that require end-customer deliveries from selected supplier(s).

This workflow provides the company with a tool to effectively transition its manufacturing strategy to a Near-Shoring model, while avoiding supply interruptions within the current supply-base. The workflow provides senior management with the assurance that the Near-Shoring project team will create a project plan to meet and/or exceed business requirements. Over the last few years supply interruptions from Asia affected all of us, hence this Near-Shoring Workflow process will help to establish a reliable supplier base for your part(s) and/or product(s).

WHO SHOULD USE THIS PROCESS

This workflow would effectively support small to large-size companies that require major assemblies and/or complete product transfers from existing supplier-base, for example, far east manufacturing to a closer home country or closer to the end customer’s region. Driven from many factors, a company’s strategy for Near-Shoring its product manufacturing can range from but not limited to the following, supplier-chain interruptions, supplier management difficulties, intellectual property protection, landed costs increase, lead-time reduction, creating a manufacturing hub within end-customer’s region, or other company reasons.