Manufacturing Automation

The automation of manual processes is a common method of improving Cost, Quality, and Throughput. So, a standardized Project Management Process is of value in reducing the learning curve for new PMs and creating a repeatable implementation process.

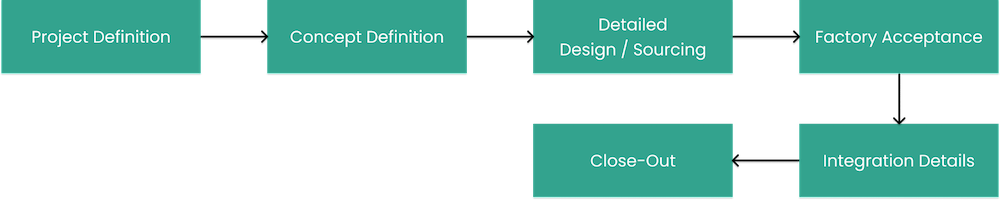

STAGES

Project Definition

Define the goals of the project. In some cases, this is an exploratory phase to identify the best opportunities.

Concept Definition

Once the Goal/Opportunity is defined, the “how” of the project must be determined. This usually involves the evaluation of several alternatives.

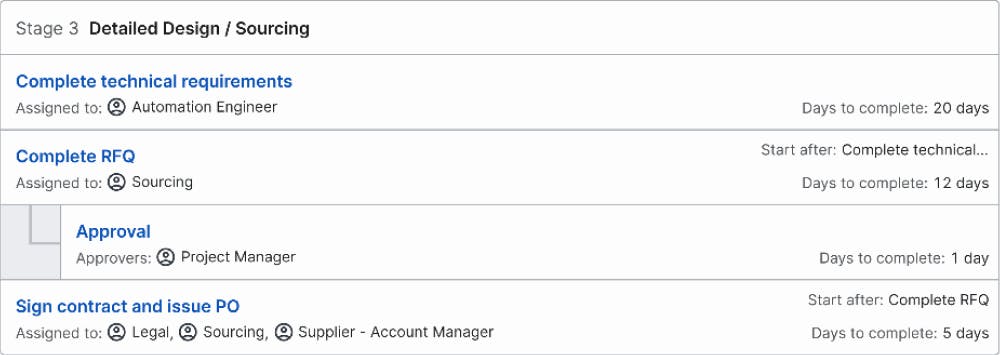

Detailed Design/Sourcing

Once the Concept is selected, the design and quoting/sourcing of the system need to be completed.

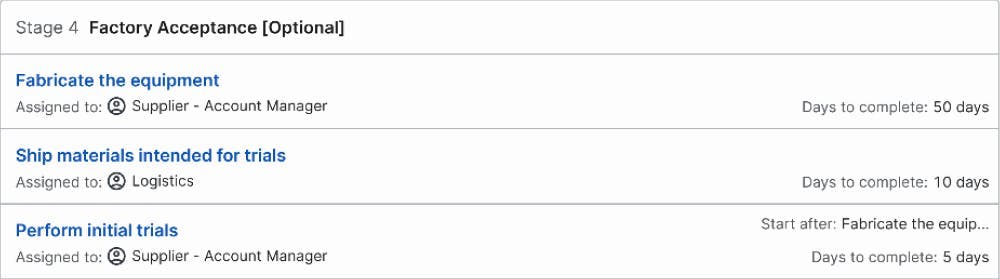

Factory Acceptance Test (FAT)

Off-site testing of equipment under simulated conditions. Depending on the complexity of the purchased equipment, this stage or parts of it can be skipped.

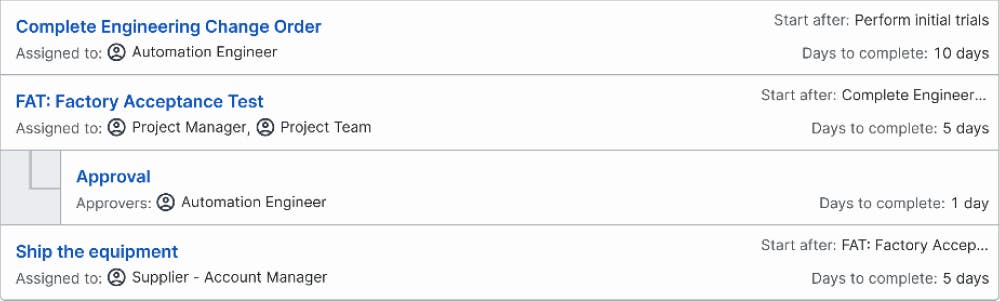

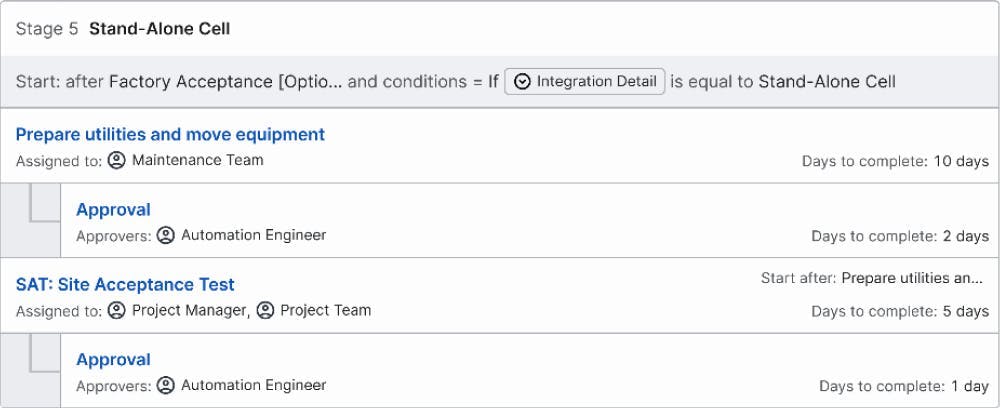

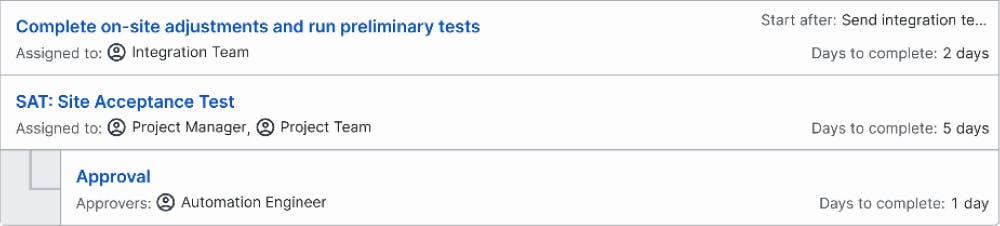

Site Acceptance Test (SAT)

This is a conditionally branched stage which is predetermined in Stage 3 as “Integration Detail”( implementation conditions explained below). Each of these stages offer a breakdown of the implementation steps and wraps up with the SAT. SAT involves testing of equipment under actual operating conditions, performing the intended tasks at agreed-upon specifications.

Stand-Alone Cell

In some cases, an automated system can be contained to a small portable booth or table. It can be as simple as a robotic inspection station that was on a table with casters to make it easily portable without even needing a forklift. A collaborative robot can be used to eliminate any safety guarding, the power source is a simple 110V outlet, and the control system is tied back to the main network via WIFI. So, integration of this system is simply pushing the table where needed, plugging it into the nearest outlet, and mapping the onboard PC through the factory WIFI. No integration teams are required to be on site; instead everything can be handled by internal Engineering and Maintenance resources.

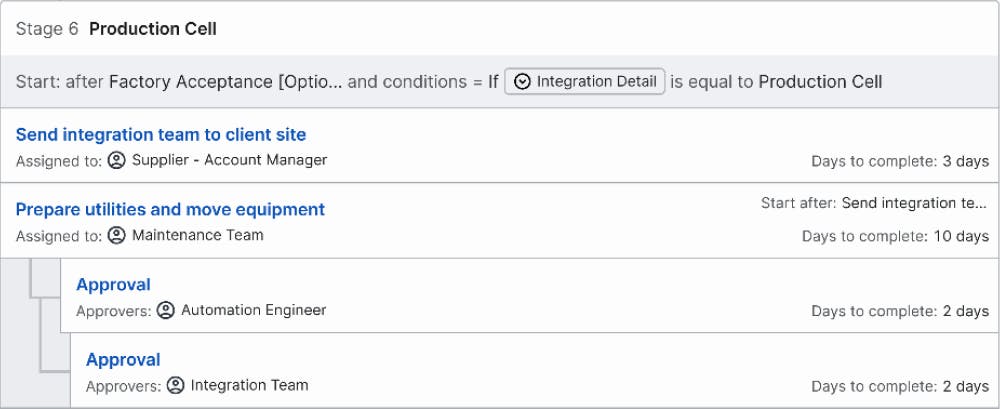

Production Cell

In some cases, the automated system may be stand-alone in nature, but requires tie-in to utilities that require much more work. A robotic welding cell, for instance, is dropped in place and ready to function before it leaves the equipment manufacturer. Typically, as a piece of equipment like this arrives, the customer's maintenance department moves all of the equipment in place, mounts everything to the floor/other infrastructure, then ties in gas lines, electrical, network IP, etc. At that point, the equipment manufacturer will come in and ensure that everything was set up correctly, then make the small adjustments to the programming necessary to actually begin production. This is usually because the relative placement between components (e.g. robot and fixture) shifts slightly upon transportation.

Automated Section of an Existing Line

The most complicated case is when dropping in a piece of equipment into an existing process. This probably involves removing a section of the existing process, connecting sensors/controls from the adjacent processes, then restarting the overall process while testing the new automated section. This requires coordination of line downtime for the entire process (or a bypass process), and also requires coordination of resources between the equipment manufacturer and the customer's engineering and maintenance teams. That coordination has to be planned well in advance in order to avoid chaos and unnecessary downtime. There is an advantage to giving this work entirely to the integrator in order to keep all of the accountability on them, but that comes with a cost. Their labor will almost certainly be more expensive than using internal resources, but there is a safety in having "one throat to choke".

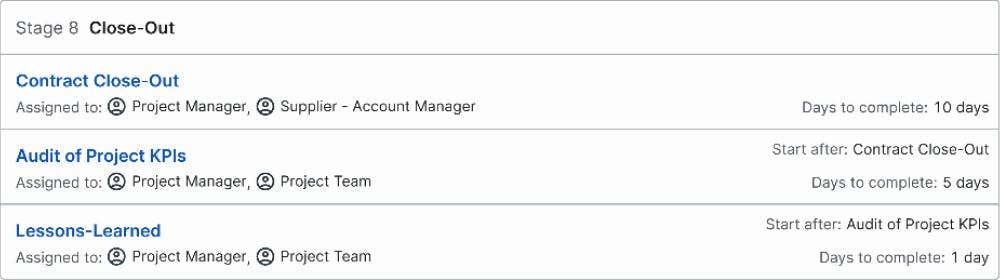

Close-Out

Lessons Learned, Audit of Results, etc...

WHY USE THIS PROCESS

Using the right suppliers is vital. This supplier qualification workflow offers the best practices for a smooth onboarding of any new vendor. It walks you through the responsibilities of a sourcing department to buy new products/services or for a new tender to find better suppliers. The department's responsibilities include identifying potential vendors, verifying required documents and agreeing on key contractual terms. This process will mainly involve internal departments such as finance, legal and quality, and externally an account manager from the supplier’s side.

A well-defined supplier qualification process is key for a company, as it accelerates the supplier onboarding while ensuring that all necessary actions are performed in the best sequence. Since the requirements for involving a supplier have increased dramatically over the last years, it is well worth it to use a standard process to onboard new suppliers, and to keep that process up to date.

This workflow offers the detailed know-how to guide a diverse team throughout a supplier qualification process. This strategy is standardized and thus replicable. It will help to properly assess suppliers as material purchase costs can add up to over 50% of the total revenue, so this will have a major impact on company profit. At the same time, having too many suppliers requires additional effort, leading to extra cost for maintaining the data and relationship.

Qualifying a new supplier is an important step prior to allowing an external company to deliver required goods on a regular basis. For innovative companies, accelerating the onboarding of new suppliers with this workflow, will shorten the integration of new suppliers in the product development process and may even reduce time-to-market for some new products, as suppliers can be integrated earlier in the development process.

WHO SHOULD USE THIS PROCESS

This blueprint is relevant to producing companies or trading companies without special regulatory requirements, excluding special industries, such as Aerospace & Defense, Medical, which require additional regulatory clearance or further adherence to export laws.

The target size for this blueprint is a mid-size company or larger. The supply chain due diligence activities are included for European or German companies and may be omitted in other countries. Smaller companies may want to streamline the process.