Supplier Qualification

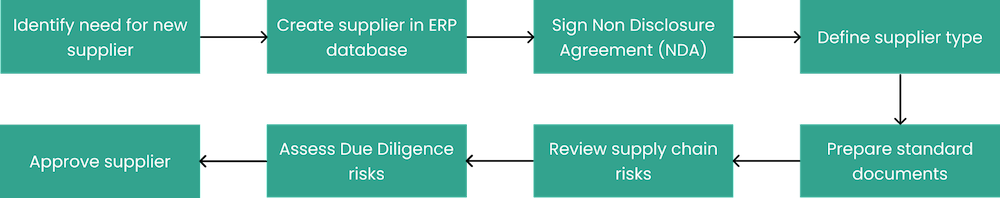

After a potential supplier has been identified, a company needs to ensure that all required documents are available and the key contractual terms are agreed, before a first order is executed. The supplier qualification process ensures a smooth onboarding of the new supplier. New suppliers may be needed during product development, in buying new services or for a new tender for finding better suppliers. Depending on the size of the organization, the supply chain, the purchasing or a strategic sourcing department is responsible for onboarding new suppliers.

STAGES

Identify need for new supplier

The supplier qualification process is triggered with the need of a department or project for a new supplier. The employees require a new partner so they contact purchasing to vet the supplier. The first step is to identify the right contact person at the supplier and start a first exchange. Once the supplier is identified, key information, such as name and additional contact details need to be collected.

Create supplier in ERP database

The supply chain or purchasing department is responsible for setting up the supplier and checking their financial data and agreeing payment terms.

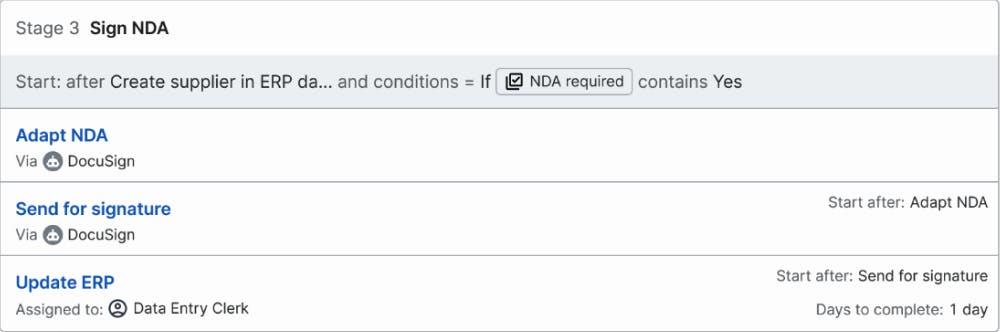

Sign Non Disclosure Agreement (NDA)

Since most information exchanged will have a high degree of confidentiality, a non-disclosure agreement (NDA) will form the basis for a more detailed dealing between the partners. Especially for suppliers producing a design of the company or developing a custom-designed new part will require a lot of information exchange.

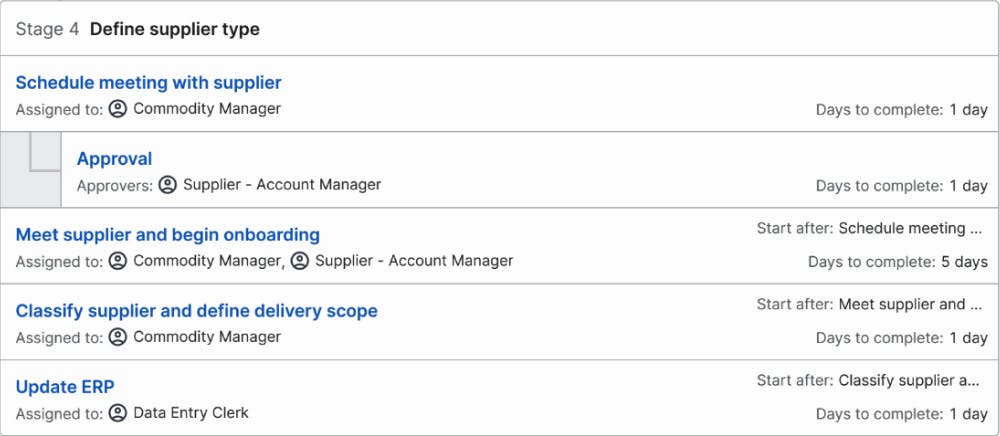

Define supplier type

After signing the NDA, the key information for the supplier is collected to set up the new partner in the material management system. Typically, purchasing related data and accounting data have to be maintained. Depending on the stage of the process, the new supplier may be preliminary released for sample, prototype or pre-series orders

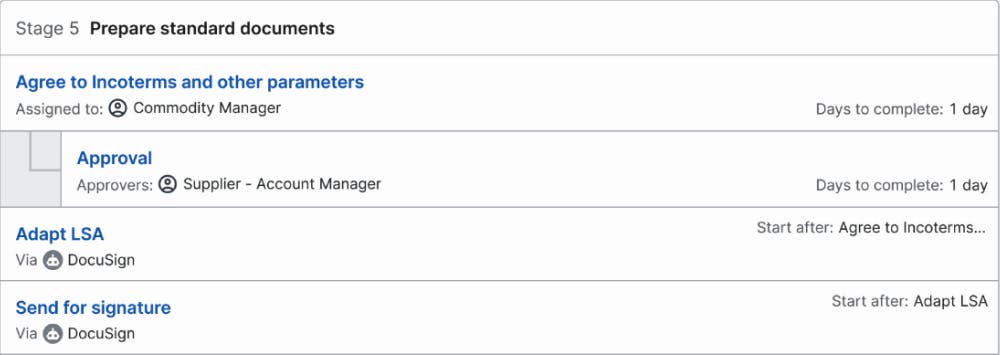

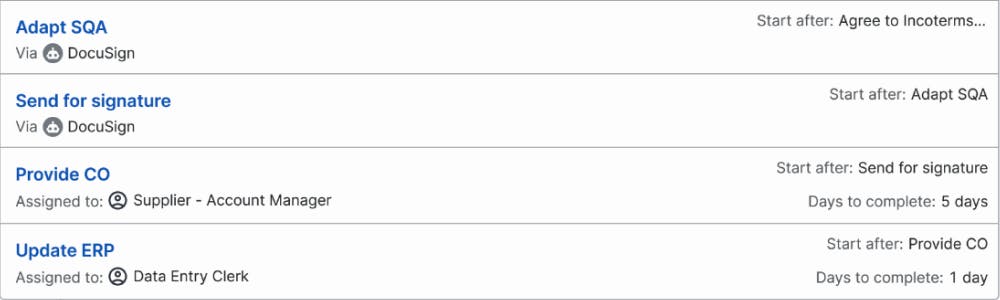

Prepare standard documents

The key terms for the future relationship have to be defined, such as quality standards and Incoterms defining the transfer of risks and ownership. At the same time, the standard parameters for quality and logistics have to be discussed, requiring a supplier quality agreement for key quality parameters and a logistics service agreement to agree the delivery types used.

Review supply chain risks

Understanding supply risks is critical in ensuring continuous delivery. While in stage 1, the checking of the fit includes some preliminary risk assessment details. This stage will review the risks of this supplier in more detail.

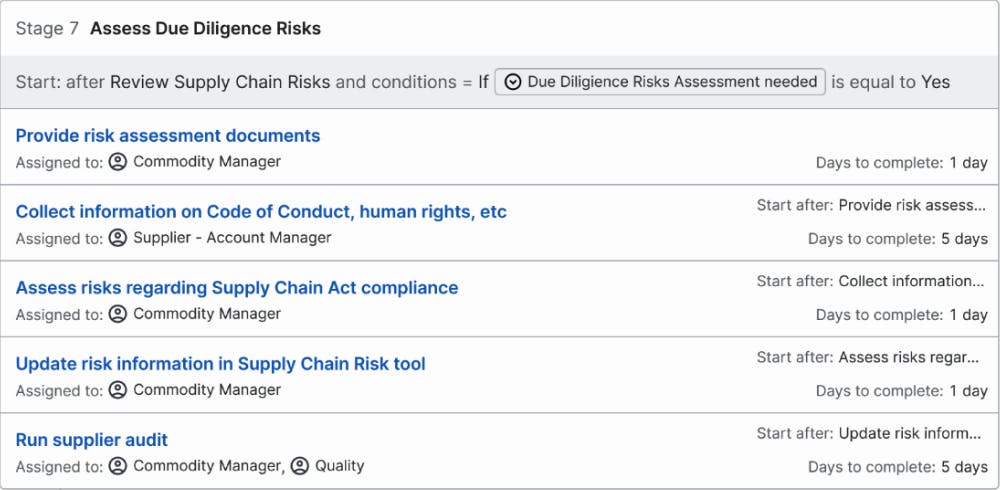

Assess Due Diligence risks

With the heightened awareness of environmental and human rights, supplier risk is becoming more important. In some countries, a supply chain due diligence process is already in place, which is expected to extend to many other countries. This requires the supplier to support a code of conduct and declare adherence to several key corporate social responsibility policies. This step is optional for companies in countries that do not require a formal supply chain due diligence process.

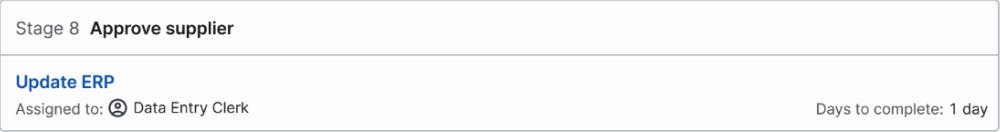

Approve supplier

Once the process is completed, the supplier is released in the system as qualified and now the supplier will receive all kinds of requests for quote, purchase orders, including serial delivery.

WHY USE THIS PROCESS

Using the right suppliers is vital. This supplier qualification workflow offers the best practices for a smooth onboarding of any new vendor. It walks you through the responsibilities of a sourcing department to buy new products/services or for a new tender to find better suppliers. The department's responsibilities include identifying potential vendors, verifying required documents and agreeing on key contractual terms. This process will mainly involve internal departments such as finance, legal and quality, and externally an account manager from the supplier’s side.

A well-defined supplier qualification process is key for a company, as it accelerates the supplier onboarding while ensuring that all necessary actions are performed in the best sequence. Since the requirements for involving a supplier have increased dramatically over the last years, it is well worth it to use a standard process to onboard new suppliers, and to keep that process up to date.

This workflow offers the detailed know-how to guide a diverse team throughout a supplier qualification process. This strategy is standardized and thus replicable. It will help to properly assess suppliers as material purchase costs can add up to over 50% of the total revenue, so this will have a major impact on company profit. At the same time, having too many suppliers requires additional effort, leading to extra cost for maintaining the data and relationship.

Qualifying a new supplier is an important step prior to allowing an external company to deliver required goods on a regular basis. For innovative companies, accelerating the onboarding of new suppliers with this workflow, will shorten the integration of new suppliers in the product development process and may even reduce time-to-market for some new products, as suppliers can be integrated earlier in the development process.

WHO SHOULD USE THIS PROCESS

This blueprint is relevant to producing companies or trading companies without special regulatory requirements, excluding special industries, such as Aerospace & Defense, Medical, which require additional regulatory clearance or further adherence to export laws.

The target size for this blueprint is a mid-size company or larger. The supply chain due diligence activities are included for European or German companies and may be omitted in other countries. Smaller companies may want to streamline the process.