New Product Introduction (NPI) - Contract Manufacturing

Standardizing the New Product Introduction process drastically reduces risk by providing a clear timeline and guide posts for the inherently variable execution phase. Delays in NPI result in missed launch dates, wasted marketing dollars, burned engineering time, and opportunity costs versus launching a different product. Improving the control, visibility, and reliability of this process is of primary importance to leadership in any product company.

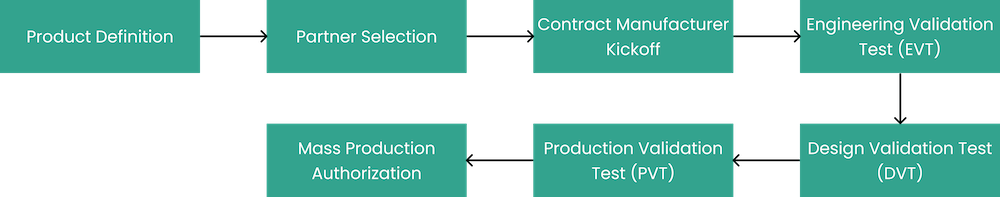

STAGES

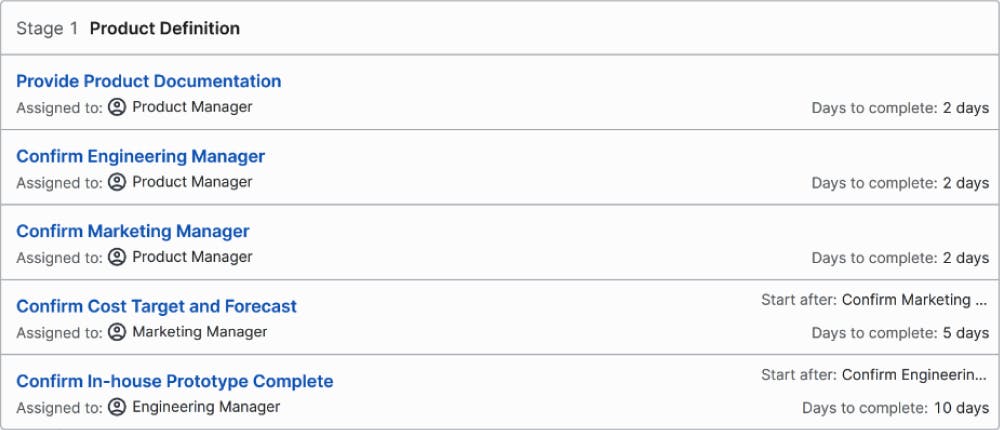

Product Definition

The critical aspects of this stage are cross-departmental, and often conducted with direct executive overview. They often pre-date the product manager’s assignment, and are thus designed to be covered retrospectively by Regrello’s data-absorption capabilities. Standardizing a company’s forecasting structure, market definition requirements, and pricing decisions into reference documentation enables ongoing process improvement without creating the separate workload these ideas sometimes require. Likewise, standardizing engineering deliverables for new products around the components, prototypes, and limitations creates an easier method for comparison when companies are proposing multiple products for winnowing pre-launch.

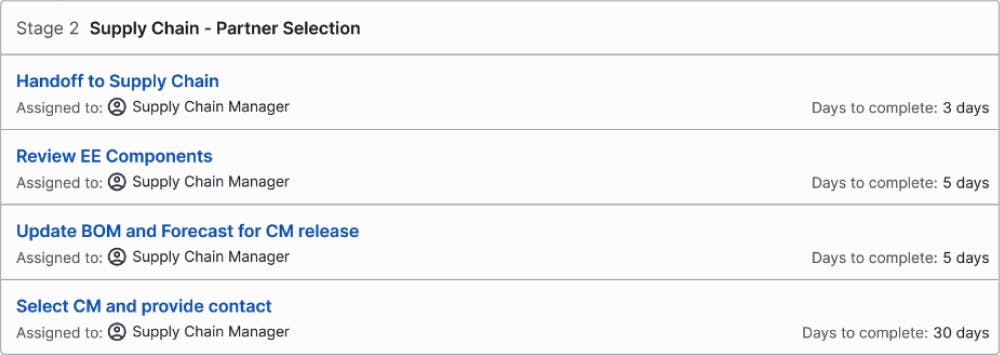

Partner Selection

This stage hands off data to the supply chain team, enabling them to work on confirming sourcing for critical parts, subcomponent assembly options, and a full package Contract Manufacturer (CM) partnership. By providing the supply chain contact with all required data, Regrello enables an efficient and transparent handoff process. Regrello can also be used for the supplier qualification work, if there’s an approval process prior to the outreach or quoting of a new product with a specific vendor.

Contract Manufacturer Kickoff

This stage initiates the external portions of the NPI process. By seamlessly inviting, onboarding, and integrating supplier contacts (be they in project management, quality, or engineering) into the NPI workflow, Regrello creates the connections and visibility that provides executives with the data they’re seeking, while easing the supply chain team’s communication and update responsibilities.

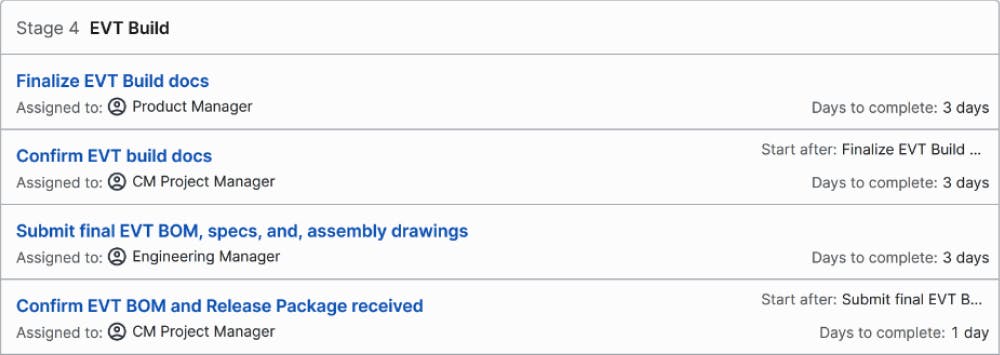

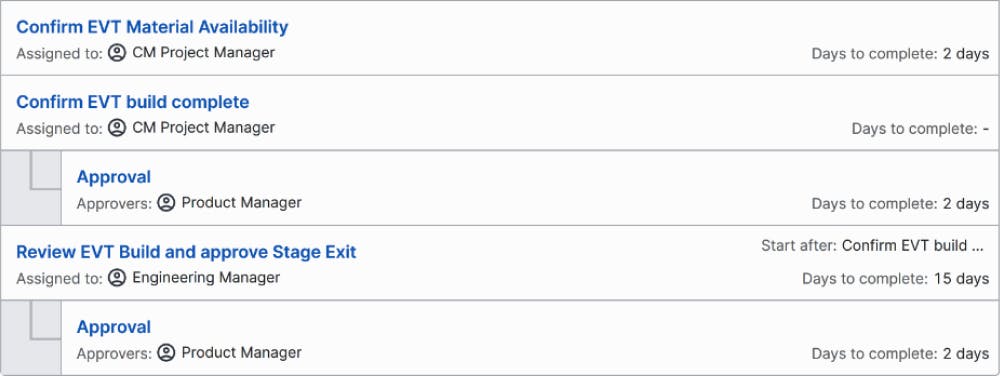

Engineering Validation Test (EVT) Build

The first build stage is designed to begin a repeatable forecast, order, document, build, summarize, and review process that will be repeated for all of the following stages. By centralizing the flow and standardizing the deliverables, Regrello’s guide creates known expectations from both the CM team and the internal roles, leading to clear approval points and outcomes.

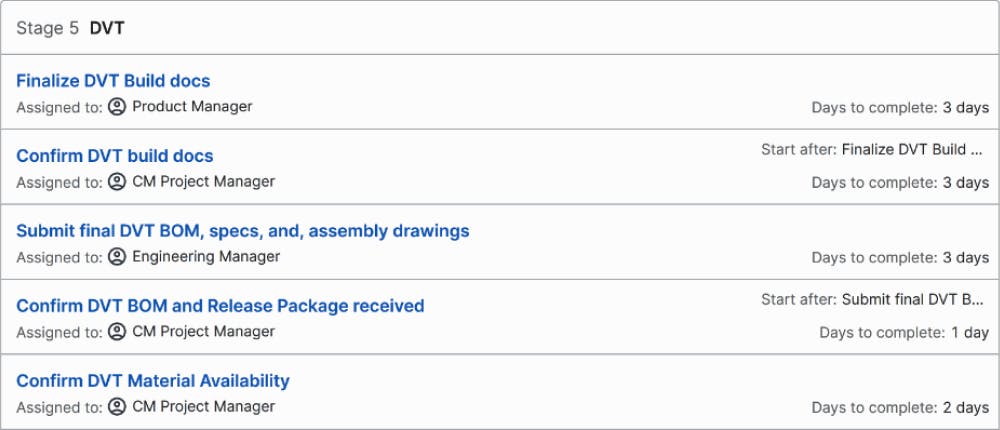

Design Validation Test (DVT) Build

Similarly to EVT, the DVT stage outlines a specific build with the required documentation provided before, during and after the action.

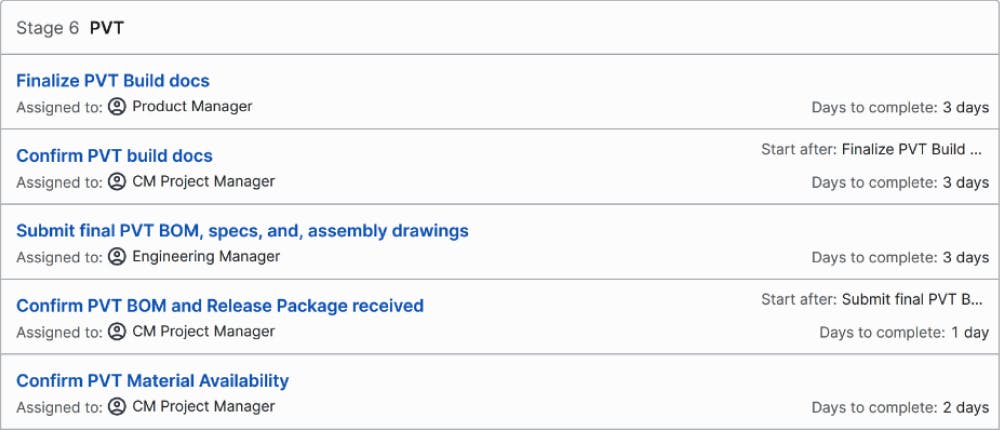

Production Validation Test (PVT) Build

The last pre-production build, PVT represents a full-fledged purchasing and qualification process.

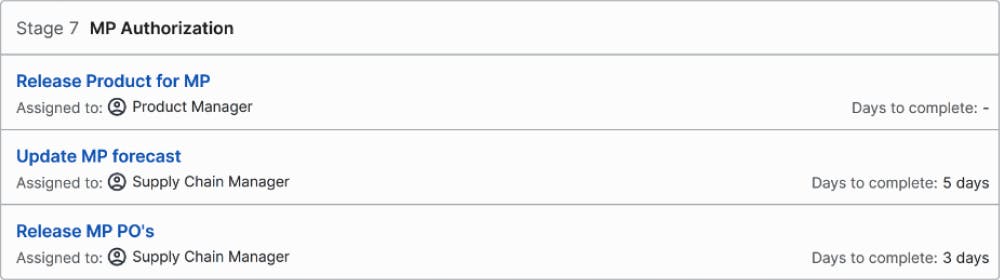

Mass Production (MP) Authorization

The final sign off that exits the NPI process, the MP Authorization stage takes a product out of development and into the ongoing sustaining phase, while also confirming details around cost, volume, and output yield for teams requiring that information.

WHY USE THIS PROCESS

In most product companies, the NPI process is long, complicated, and full of risk. Companies aim to introduce new products on a particular cadence, often targeted at seasons or specific launch dates. Be it “back to school” for a laptop or backpack, or “summer” for a new barbecue, cooler or line of swimwear, the combination of a tight launch window with the uncertainty of product development leads to stress and possible delays. Every company would like to standardize the NPI process, and create a reproducible development capability with predictable outputs. While this dream may be out of reach, a better process with more reliable checkpoints and visibility is not.

The main benefits lie in the standardized structure and expected reporting capabilities that come with said structure. Breaking down the process into clearly defined stages and limiting the variability between projects gives the project managers, and by extension executives, better understanding of each specific project’s challenges and risks, while also enabling personnel to switch projects more quickly. In addition, by documenting the compliance, performance, and engineering requirements in similar manners, past projects become learning material for new employees, allowing lessons learned to more automatically guide future decisions.

WHO SHOULD USE THIS PROCESS

This NPI process is most applicable for mid-sized companies, specifically those in consumer electronics, as the structure, vocabulary and author’s experience lie in that field. It can be, with modification, applied to other industries. Smaller entities can definitely use what’s presented, and it should help avoid common pitfalls, however the documentation expected and roles outlined may be beyond Kickstarter startups or first-product operations. Similarly, global entities with established product pipelines will already have much of what’s outlined built or incorporated into teams or operations within their existing structure. While they too can usually benefit from thinking holistically about the process, their main benefit from Regrello’s compendiums will come from the high-level visibility provided by moving communication out of email and into a specific project-focused workflow, enabling reporting and cross-product learning.

Otherwise, this guide should be of benefit to everyone creating physical goods at a factory-scale, be it in collaboration with a supplier, a more rigid CM, Electronics Manufacturing Service (EMS) or Original Equipment Manufacturer (OEM) structure, or a more closely constructed partnership.