Factory Setup

The following process blueprint outlines a general process and overview for setting up a new Production Factory. New factories are industrialized every day across the world, sometimes as a start-up, sometimes as an expansion of a larger, existing enterprise. In any case, the required tasks and associated lead times can be adjusted to match the scope of the project in question. There are many inputs into the decision of how and where to set up a new factory. The dominant quantitative inputs are Freight, Wages, Real Estate costs, and Government Incentive opportunities. There are several qualitative inputs that should not be discounted: skilled-labor availability, attractiveness to relocate, proximity to customers and competitors, proximity to seaports and airports, and so on.

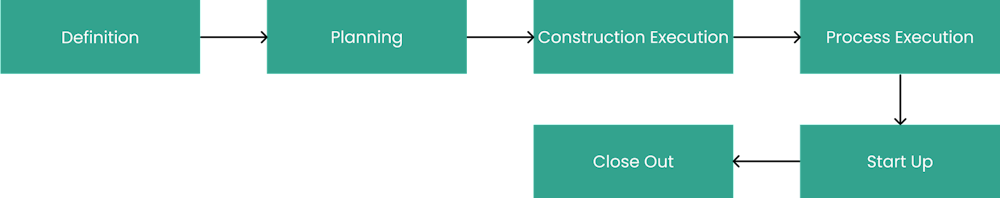

STAGES

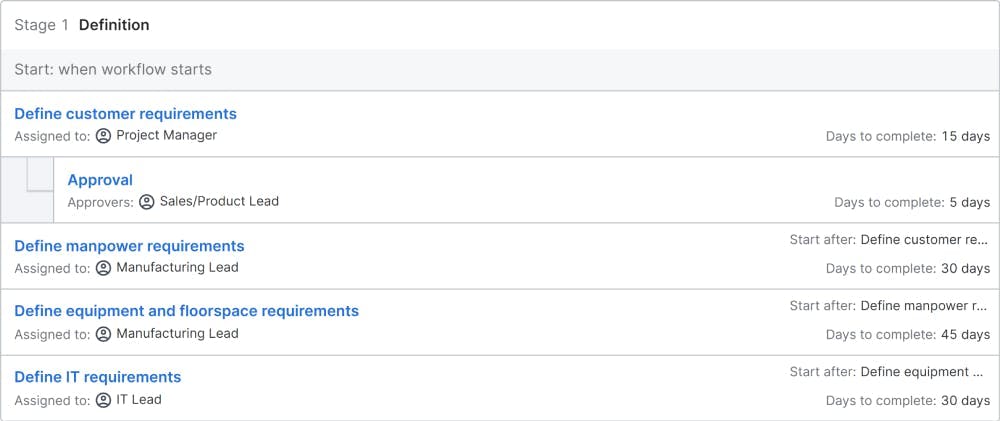

Definition

The first phase focuses on defining the end state of the project: production requirements and capacity, risk planning, budgeting, and so forth. This should always start with the Sales and Product plan (the customer).

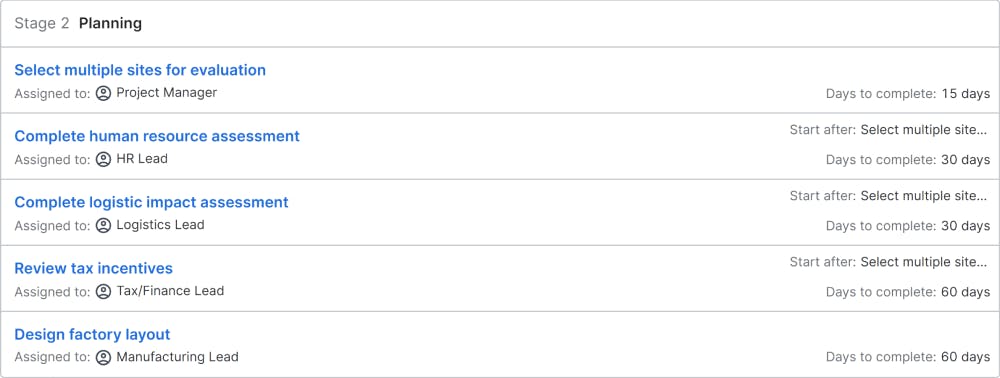

Planning

With defined goals and customer requirements in place, the second phase is spent designing a manufacturing system that meets those business needs. This includes floorspace, equipment needs, manpower needs, site location, etc. The tendency of most companies is to rush through the first two phases and “figure it out as we go” during the later phases, but this is usually a very costly approach due to change orders or a sub-optimized manufacturing system that might have been averted with more detailed Definition and Planning phases.

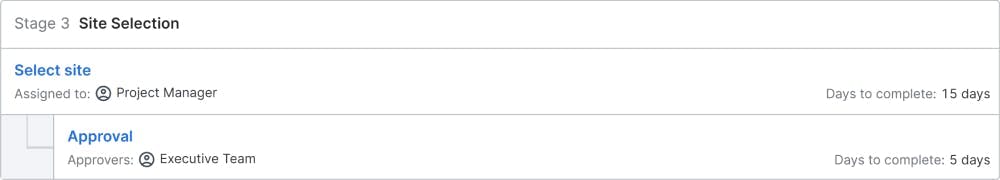

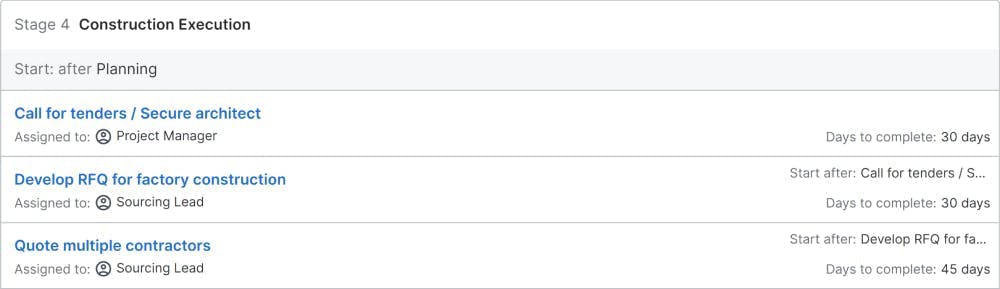

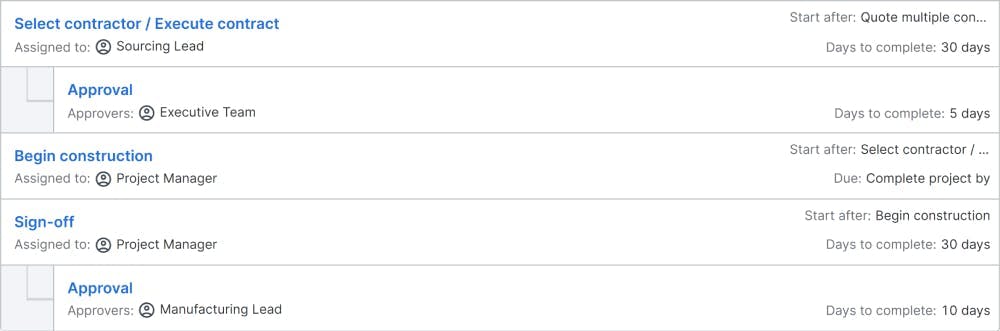

Construction Execution

With a plan decided upon, the third phase is spent constructing the facility and infrastructure. This phase can be reduced by leasing an existing building.

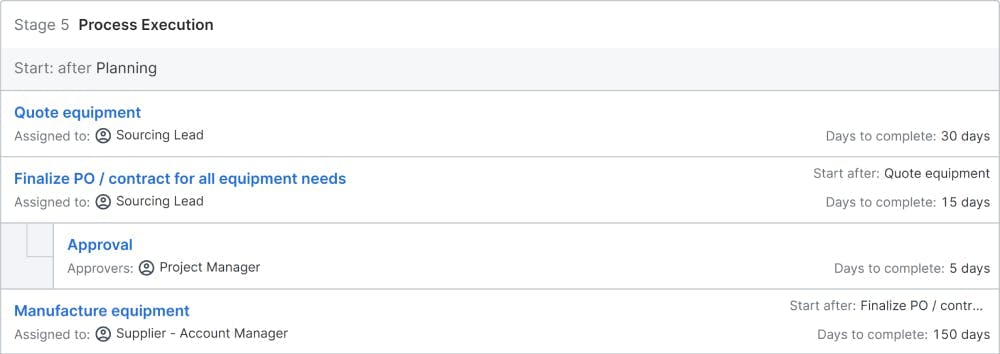

Process Execution

The fourth phase is sourcing, manufacturing, and industrialization of all the needed process equipment. This phase is often in parallel to the Construction process.

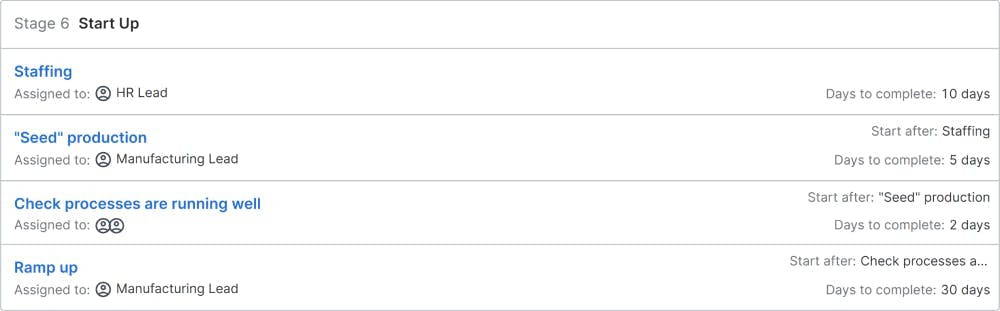

Start-Up

The fifth phase is start-up and ramp-up of the new factory.

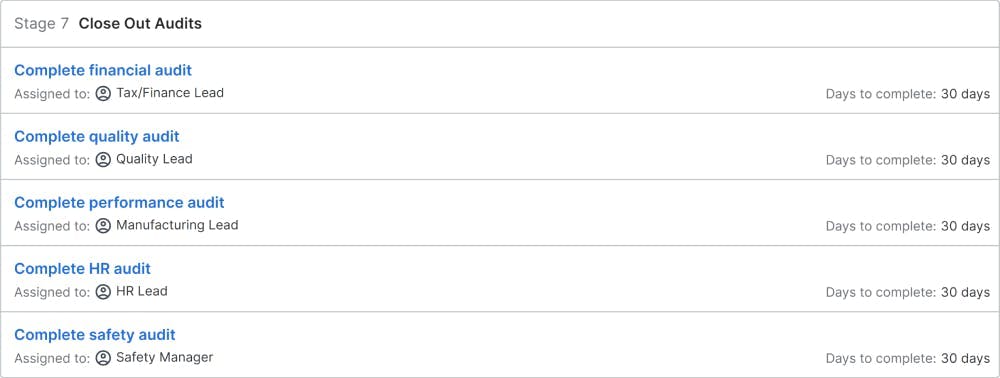

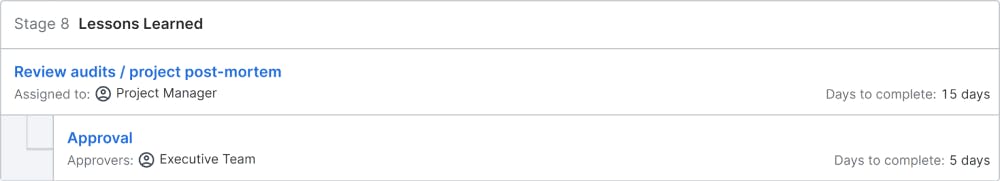

Close-Out

The final phase of the project is to review all actual metrics relative to the goals at the onset of the project. Understanding what did not go to plan is essential to reducing failure in future projects. Also, corrective actions should be put in place for all deviations from planned metrics.

WHO SHOULD USE THIS PROCESS

The structure of the outline is intended to be as large of scope as possible, to include new Building Construction, new Equipment, and Staffing. Elements can be removed or shortened based on actual project needs. For instance, a start-up may choose to rent/lease a property in order to minimize capital investment and lead time. On the other hand, an established enterprise may elect to build its own facility in order to customize the building design to fit its operation more optimally. This template may apply to almost any industry: Automotive, Consumer Packaged Goods, Food, Chemical, Medical Devices, etc. This template could be reduced dramatically to fit an Outsource or “3rd Party Manufacture” project, in which case the focus is on equipment, tooling, and process validation.

WHY USE THIS PROCESS

This process is usually the responsibility of an organization’s Head of Manufacturing, but managing the workflow is more often delegated to an individual or team of Project Managers. A project like this can consume extremely high amounts of Capital, and do so irreversibly, so the value of utilizing a robust process in execution cannot be understated. The value of upfront planning, thorough due-diligence, and detailed project management throughout the project will ultimately reduce project lead times, investments, and overall operating costs.

Having a robust process established for Project Managers to follow will drive accountability, enhance communication, and ultimately should lead to shortened project lead times and reduced spending. The inclination of many companies is to rush through the upfront planning work in order to hit a key date, but this almost always leads to incremental costs downstream in the project when the customer has very little leverage against the vendors/contractors. So, emphasis on robust inputs from the business and thorough due diligence in the early phases of the project are absolutely key to a good result in the end.