Procure to Pay

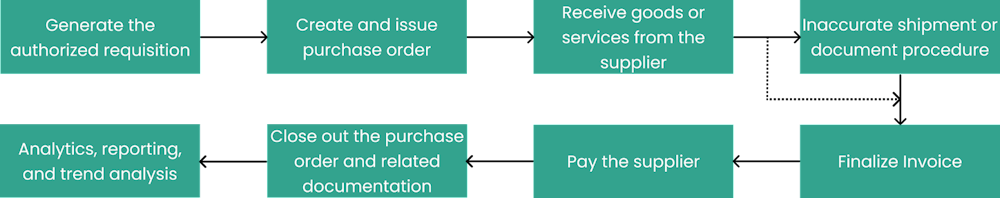

Procure-to-pay (P2P) is a fully integrated, automated, and closed loop system used to support an end-to-end process that begins with the requisition of goods and services and ends with payments to suppliers. It is often an e-procurement core functionality that includes e-requisitioning, workflow and approval, and in some cases e-catalog management.

P2P is used by organizations to manage and track the acquisition of goods and services. The process includes activities such as creating purchase requisitions, issuing purchase orders, receiving and inspecting goods, processing invoices, making payments to suppliers and analyzing related analytics.

Overall, the use of technology in the P2P process has allowed companies to increase the speed, accuracy and efficiency of the process, reduce costs and costs, and improve the overall efficiency and effectiveness of the procurement activities.

STAGES

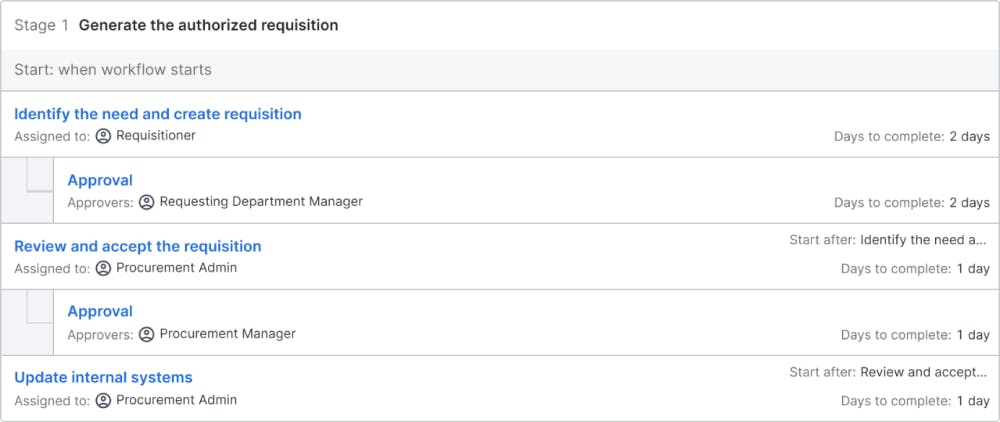

Generate the authorized requisition

The requisition process begins when a department or business unit identifies a need for a good or service. A requisition document is created outlining the specifics of what is needed and the budget for the purchase. The requisition can be stand alone for indirect items such as lab supplies or marketing services. Direct inventory requisitions are typically generated by ERP or MRP systems. Any requisition should be properly approved before it is sent to procurement for action.

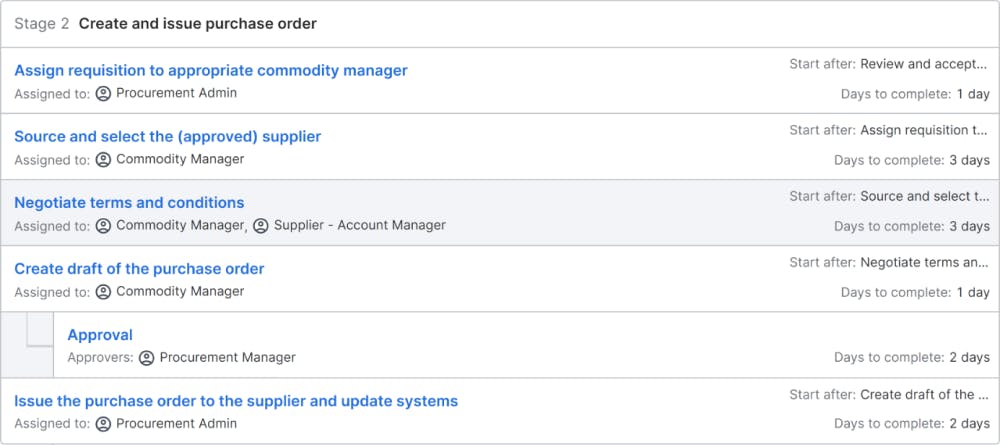

Create and issue purchase order contract to the supplier

The requisition is received by procurement then reviewed for completeness and approved by the appropriate procurement department manager. Once approved, the requestion is assigned to the pertinent commodity manager. After sourcing and negotiation, a purchase order is generated and sent to the supplier. Note that there may be an existing blanket order or systems contract in place and the requisition is turned into a formal release of a product or service, rather than a discrete purchase order.

Receive goods or services from the supplier

The supplier sends an invoice to the company for the goods or services provided along with packing lists and other relevant shipping documents. The supplier ships the goods or provides the services, and the receiving department confirms receipt of the items and verifies that they match the quantity description on the purchase order. Discrepancies in count or description is reported to the commodity manager for resolution. Those in receipt of services should notify the commodity manager of successful completion so the service can be ‘received, the purchase order closed, and the supplier paid. Direct material may be routed to quality control for review or sent directly to inventory.

Electronic invoice processing systems can automatically match invoices to purchase orders and receiving reports, reducing the need for manual data entry and reducing the risk of errors.

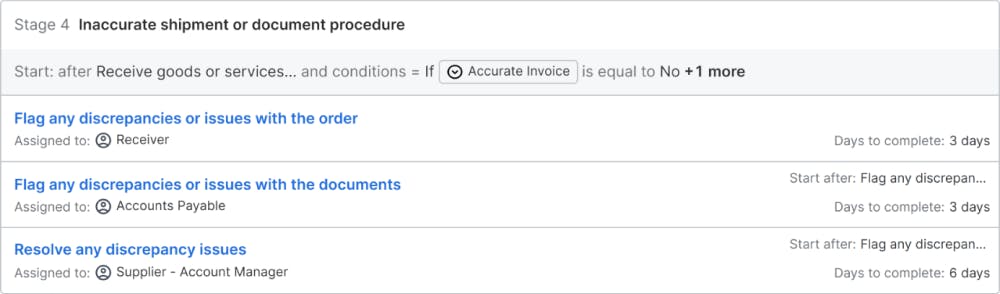

Inaccurate shipment or document procedure

This is a conditional stage that will only start in case discrepancies are reported in the receiving or invoicing processes. Discrepancies are handled on an exception basis by the commodity manager, coordinating with accounts payable and receiver to report to the supplier and resolve.

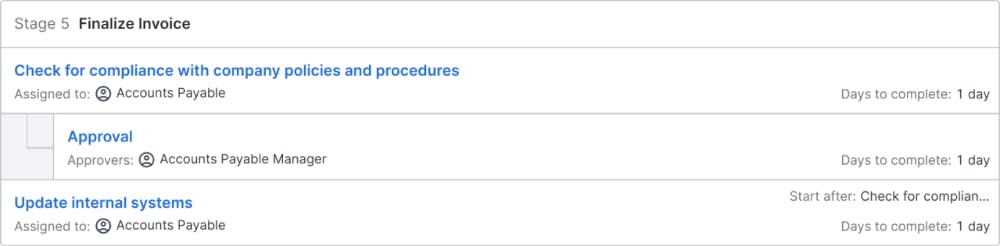

Finalize invoice from the supplier

If the invoice matches the purchase order, and the goods and services properly received, the invoice is checked for compliance with company policies and is then considered approved for payment. In some instances, invoice may be reviewed by the appropriate department or business unit manager of the original requisitioner and approved for payment.

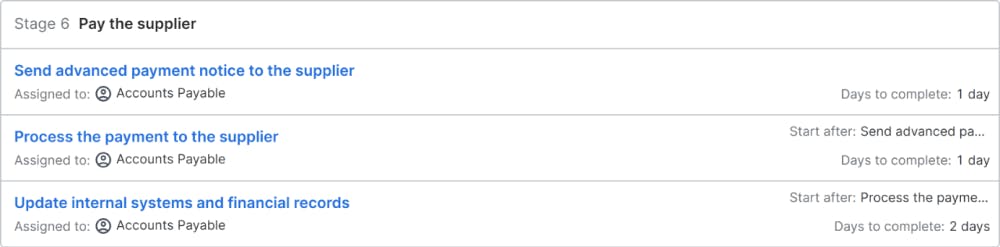

Pay the supplier

The company makes payment to the supplier according to the terms of the purchase order and invoice.

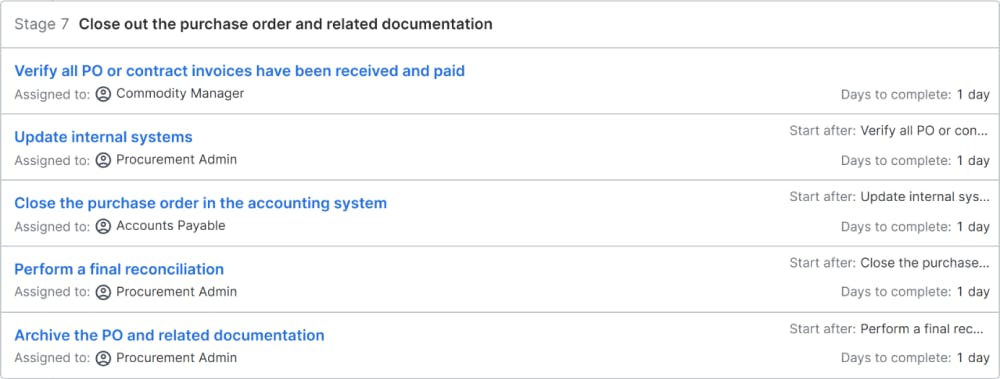

Close out purchase order and related documentation

The purchase order and all related documentation are archived for future reference and to ensure compliance with company policies and procedures.

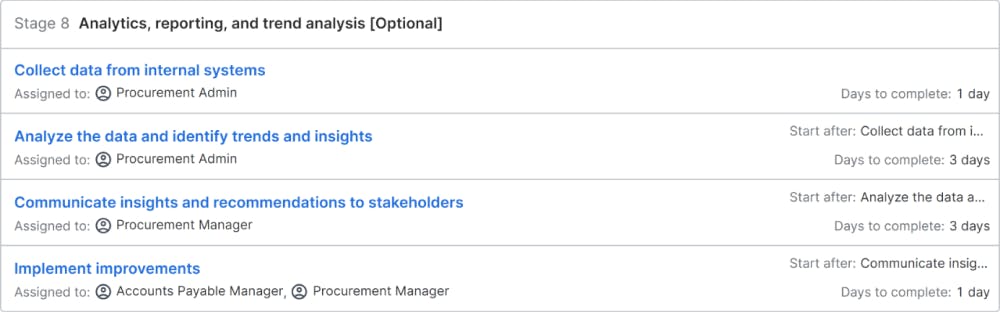

Stage 8: Analytics, reporting and trend analysis

Track and analyze data related to their P2P process, such as spend by category, supplier performance, and requisition, purchase order and invoice processing time. Identify and act on areas for improvement.

WHO SHOULD USE THIS PROCESS

Consider that the procure to pay methodology is a fundamental one used in companies of all sizes in manual, semi-manual or fully automated processes. It is optimally a closed loop system where the need is recognized and approved, the purchase order contract is let by a formal agent of the company, goods and services are properly received and inspected, the supplier invoice is matched with the purchase order and is subsequently paid by the accounts payable department. Companies can implement P2P using manual processes, spreadsheets, or specialized software, depending on the size and complexity of your business.

For the purposes of this blueprint, the procure to pay process (P2P) is an automated one, albeit one that depends on human involvement to fix requisition, purchase order, receiving, and accounting discrepancies. It is incumbent on companies to fully map out a relevant process that works for their company, leveraging automation and minimizing exceptions.

WHY USE THIS PROCESS

P2P systems automate many of the manual tasks involved in the procurement-to-pay process, such as requisitioning, purchase order creation, invoice processing and making payments to suppliers, thereby increasing efficiency and reducing errors. P2P systems provide visibility into the entire procurement process, allowing managers to track and monitor progress and make adjustments as necessary.

P2P systems can help companies achieve cost savings by automating the procurement process and identifying areas where cost savings can be achieved, such as by consolidating spend on certain goods or services, or by negotiating better pricing with key suppliers. These systems can help ensure compliance with company policies and procedures as well as meet regulatory requirements. In addition, P2P systems provide a centralized location for the management of data related to the procurement process, such as supplier information, purchase order history, and invoice data.

The procure-to-pay process interfaces with Enterprise Resource Planning (ERP) systems in several ways. P2P processes and ERP systems are integrated, allowing for the uniform flow of information between the two systems. This eliminates the need for manual data entry and reduces the risk of errors in the creation of purchase requisitions, purchase orders, and the processing of invoices and payments.

By using P2P, companies can streamline and standardize procurement processes, reduce manual effort and errors, and increase visibility into spending and supplier performance. Regularly reviewing and assessing the P2P process, and incorporating feedback and suggestions, can help identify areas for improvement, and lead to a more efficient and effective process over time.

Adherence to supplier payment terms is a critical and overlooked aspect of supply management. Companies that work closely with suppliers to ensure that their invoices are paid within terms are considered excellent customers, given that many companies tend to delay payments for a number of reasons, including cash flow, poor P2P processes, or ambivalence. And good customers that pay their bills typically get excellent supplier performance.