How to Outsource a Manufacturing Process

Many companies are concentrating on their core competencies. Many companies have successfully outsourced manufacturing. What is needed to outsource manufacturing processes? There are several key steps to run a successful manufacturing outsourcing project. After describing the electronic assembly as a case study for outsourcing manufacturer, this paper focuses on the key activities, such as selecting the right partner, setting up the outsourced manufacturing, implementing outsourcing in the IT systems.

Outsourcing Manufacturing: a Case Study for Electronic Assembly

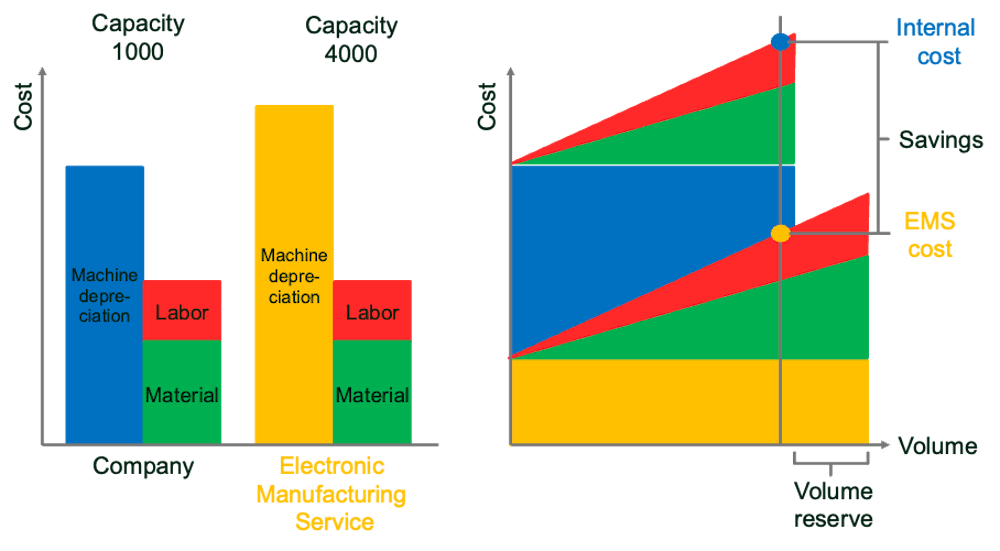

Outsourcing manufacturing has been a logical approach for many electronic companies. In this industry, many successful companies, such as Apple or Cisco (Lee & Schmidt, 2017), do not operate an own production. Electronic assembly equipment is very expensive. The same equipment can be used for many different products. The bigger and more expensive the equipment, the faster the assembly speed and the higher the assembly quality. Higher speed and lower labor costs for monitoring the highly automated machines lead to lower cost per printed circuit board (PCB) assembly. With the higher speed, there is also a possibility for the company to have a volume reserve.

Figure 1: Cost comparison internal vs external production

Electronics assembly is a great showcase to show the effects of outsourcing the manufacturing process. While the design of the PCB remains in the hands of the company selling the product, the electronic manufacturing service (EMS) (van Liemt, n.d.)company is responsible for the assembly of components on the PCB. These service providers have specialized knowledge in assembly and testing, they own efficient, highly automated equipment that can produce the highest quality. The more these machines are used, the lower the overall cost for the EMS company and the lower costs it can offer to a customer. EMS companies have a much larger production volume than their customers, leading to lower assembly cost and a cost advantage for the EMS company. The key issue in electronic assembly is not the wages, but the distribution of high investment cost on more components to be placed.

Selecting the Right Partner

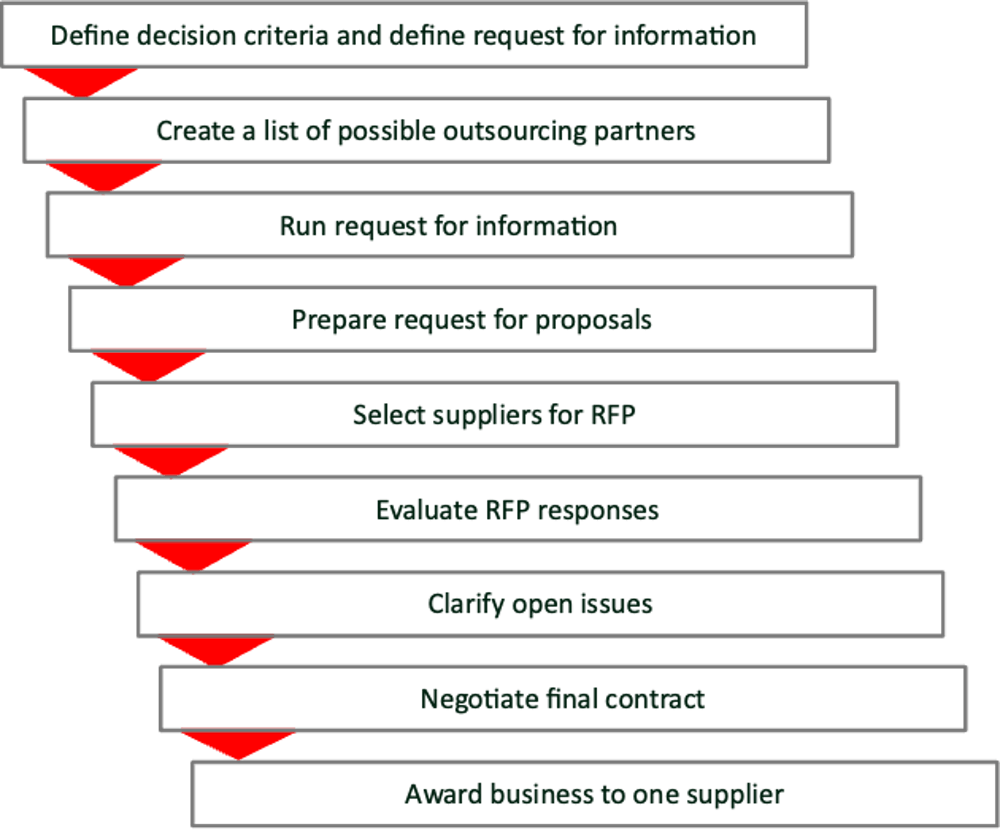

The objective of the outsourcing process is finding the right partner. Since the decision to move production to an external partner has impacts on cost, quality, delivery time and flexibility, many companies spend a lot of effort in defining the requirements for the outsourced manufacturing steps. Defining and weighting the main decision criteria – which objectives are important or not – is the first step.

Figure 2: Process for outsourcing manufacturing

The next step is to create a list of possible outsourcing partners. If there are more than 3 possible partners, there is a need for starting a request for information (RFI) process (Scott et al., 2018), which will narrow the list down to 3-4 candidates. The aim of the RFI process is to identify the best fit partners for the outsourcing objective. If the outsource objective is to reduce cost, the key criteria for selection should be cost. Sometimes, delivery time or lot sizes for highly variant products are more relevant. The criteria will usually not only include the technical capability (size of PCB, sizes of components, quality and inspection technology used), but also financial data, such as financial stability of the new partner, and strategic fit. It also important to check available production capacity and get references. The company will define a template for the answers to the questions that are used to evaluate the suppliers. The template is sent to all participating companies of the RFI.

While the potential partners fill out the RFI return document, the company can prepare for the next step, the request for proposals (RFP) (Martel & Klibi, 2016). The company will select representative products for which they will ask specific quotations and compile all the necessary data. At the same time, the scope and the contents of the RFP is defined. For which overall quantities and lot-sizes will the company need offers? What are the key criteria to select the final partner?

After the answers for the RFI process are received, the company will use the evaluation schema to select the best suppliers in the list. Reference calls will be made, if the supplier provided the requested information about customers. The list of potential suppliers will be narrowed down based on the provided answers in the template. The best three suppliers will be invited to participate in the RFp process. Since a lot of detailed technical data will be exchanged, the companies will sign a non-disclosure agreement to protect confidential information prior the RFp data exchange.

The RFP process is focused on receiving quotes and detailed information for the representative products from all three suppliers with different ordering quantities and lot sizes. The RFP answer template is built in such a way, that the information sent back from the supplier can be easily compared by the customer. Using a template, it is ensured, that the data from all suppliers are comparable. Once the RFQ answers from the suppliers are received, they are checked for completeness and any obvious errors. These can be clarified, before the evaluation happens.

Using the RFP evaluation parameters, the suppliers are ranked. Depending on the requirements, a supplier visit will lead to a preliminary quality audit result, which will be included in the selection criteria. With the selection of the best two suppliers, the company will start the final negotiations. Comparing the results will lead to one supplier, that will be awarded the business: A new supplier is selected for the outsourcing of a manufacturing step.

Setting Up Outsourced Manufacturing

Once the outsourcing partner for the manufacturing is defined, this supplier needs to be set-up for success. The supplier will need to receive all information for all products. The new supplier will review the documentation and will ask many questions to understand the products and their production as much as possible. It may be useful to identify a contact person in engineering, that will receive the questions from the supplier and collect the answers from the technical team to ensure, that no open issue remains.

The supplier has to fill their supply chain with parts and intermediate states to be able to react quickly. Depending on the scope – will the service provider only assemble the product or is the company also responsible for the purchasing of parts - setting up the supply chain will lead to increased inventory costs for the required components.

For production, maybe new fixtures are required. Programs for the assembly machines and test programs may need to be newly written or existing one rewritten. New transport containers are wanted, for internal use at the supplier as well as sending the parts to the company and storing them until they are used. The cost for the set-up is often underestimated.

Many of the described issues can be avoided with good preparation and a thorough review of the complete process. Companies are well advised to prepare for the outsourcing in detail, as these blunders may cost heavily.

Implementing Outsourcing in your ERP System

The outsourcing process needs to be set-up in the ERP system of the company (Wu & Ellis, 2000). Products need to be sent to the supplier, the work performed there, and the products need to be sent back to the company and fed back in the work process. This has an effect on production processes, bill of materials and material movements and needs to be accurately modeled in the systems.

This requires many different master data to be maintained. Since the sub-contracting combines a production step with a lot of material flows (Moving the product and all needed components to the supplier, moving the final product back). In order to identify the different stages of production progress, many companies implement different material numbers for the product before and after the outsourcing step. This will require an update of the bill of material structure, while new BOMs and routings are created.

Scheduling outsourced production activities is difficult. An ERP system cannot do a capacity check and throughput scheduling for a supplier. Usually, the systems plan with unlimited production capacity at the supplier and often with a fixed lead time. Using the different BOM levels, this can be somewhat modeled in the ERP system, but the systems will never optimize this as much as an internal production.

At the same time, the material needs to be identified, prepared for delivery and sent before the production order to the supplier. The supplier sends the material back and after receiving the goods, the product tends to be integrated back into a production work stream. The coordination of these extra steps is cumbersome and difficult.

While this covers the positive execution, what happens, if something goes wrong? Who is responsible of inventory management of the materials at the supplier? At the supplier, the material has to be managed as consignment stock, if it belongs to the customer. What happens, if a material sent to the supplier is scrap, how is this scrap accounted for? And who gets the income from the scrap, if the material is valuable? How does the supplier demonstrate, that they are not responsible for a failed product or missing material? How is the inventory of the material tracked and included in the inventory counting at both partners, the supplier and the company?

The implementation of the subcontracting process is maybe one of the most complex processes in the ERP system. SAP defines several different options and many sub-contracting process steps are added to the process execution.

What are the Expected Effects?

The key intention for many companies is to change fixed costs into variable costs. Instead of investing in expensive equipment, the companies want to pay the suppliers for the use of the fixed costs. If the supplier can share the equipment with three other companies, the cost for equipment use will be a smaller share than the own costs.

Lower labor cost, different pay based on other trade union assignment are possible root causes for the expected savings. Higher automation or higher productivity maybe other reason for the advantages at the supplier.

Sometimes, purchasing of parts is also outsourced, if the other partner has a higher purchase volume and maybe able to get better prices or part discounts. Especially with many new products, an open book policy for material costs need to agreed, if the supplier purchases the parts.

In many cases, manager at the companies expect that existing problems disappear. Due to higher and specialized know how, many quality problems should disappear, as the supplier may have solved the problem before. Higher on-time delivery, shorter delivery times are other improvements hoped for during the ramp-up. Unfortunately, the new supplier will not always be able to work wonders, and they need to get acquainted with the products and learn what are the important elements of the manufacturing processes. Many existing problems also rise to higher management levels, as they were often not raised high inside the organization and now become a conflict with the new supplier.

In summary, the realized effects are usually much lower than expected. Additionally, many companies are unhappy with the speed of the outsourcing improvements.

Avoiding Common Pitfalls

Outsourcing is a special project and not many companies have a lot of experience with this process. There are many problems, that companies have reported (Power et al., 2004).

Some of the key problems with outsourcing are the limitations of typical requests for quotations. There are typical problems like missing documentation, not describing the complete outsourcing task, the focus on representative products costs instead of the underlying cost structures, not including supplier know how in the product design, sharing risks and rewards, missing the setup costs as a cost factor influencing the decision and not including cost savings.

Missing documentation is an often-experienced fact during outsourcing. Many assumptions have not been documented and the knowledge has grown over time but was never written down. Successful transfer requires this information, that will be difficult to create during a production transfer to an outside partner.

Claims for additional work are a classic conflict issue between a company and the outsource partner. Many processes are not documented well, and certain products may require additional work. In the own factory, this additional effort is done, but not accounted for. Outsourcing the process changes this: The new supplier will charge for any extra work, e.g., putting components in a belt for easy SMD assembly or marking certain products after an additional quality check.

A quote for the costs of a specific product is required to have an easy comparison with the actual state. But this may be just a special price for one product, and other products to be outsourced are more expensive. If many products are outsourced at the same time, the effort to create quotes for the suppliers is getting very large. The solution to this problem is identifying the key cost drivers and get a quote for these drivers. If a cost structure for the key cost drivers is agreed, such as cost per placement, the company can use this information to evaluate all products and to introduce new products based on a predictable cost.

In many cases, the supplier has different equipment than the company producing the products before. A change in equipment may require new or other optimization approaches. Predictably, the soldering may need a different fixture, as the soldering oven at the new supplier may have slightly other heat distribution parameters and this may require small geometric changes in the fixture. Sometimes, different machines cannot reuse fixtures from previous equipment. It is important to understand the impact of the manufacturing process on key product parameters to improve the quality while reducing costs.

One of the key issues is the distribution of risks and rewards. What happens if the volume increases? Will the supplier reduce costs? Or will the cost stay the same for the company and the supplier will benefit from the higher quantities= What happens, if the market decline? Or the products are not as successful in the market as expected. Sharing risks and rewards will foster a long-term relationship. Short-term gains for one party will lead to dissatisfaction at the other side. Keep in mind, that the business needs to be enjoyable for both sides – and if it is, it can be the basis for a fruitful collaboration for both sides.

When evaluation the costs, the set-up costs for the change are often underestimated. What are the costs for new fixtures due to different equipment. Sometimes, more special transport containers are needed to store more products overcoming longer delivery times. Or new packaging is required to be able to transport the products from the company to the supplier. New employees at the supplier are not producing with the speed of the more experienced workers in the past, as they are learning how to execute the production steps. New master data must be entered in the ERP system. For the inventory build-up at the company, purchasing buys additional products, increasing the inventory value. Most of these on-time costs are not accounted for and will lead to discussions shortly after the start of the outsourcing.

While internal processes need to be improved yearly, the outsourcing process is typically not tasked with cost reductions over the years. In many cases, only a contract is made over a limited time, not a multi-year contract, that include a 3-5% savings per year. Even if this saving is shared between the supplier and the company, this will lead to the cost reductions, that this outsourcing needs to generate to be competitive with internal processes.

Making it Happen

Many problems as described above can be eliminated to make the outsourcing project a success. Careful preparation and integrated work between the partners is key for success. During the ramp-up, frequent visits of company experts to the suppliers should be planned and accounted for.

During the switch-over period, there is a lot of pressure on both sides. While the new supplier wants to appear competent, many problems surface in this time. For the company outsourcing the product, these problems are often new, as they have been solved in the internal production. Since the production people with the highest knowledge most probably are not there at the company anymore, some tricks will not be transferred to the supplier.

It is important to install a project manager to oversee the outsourcing project. She or he will manage the issues that arise and will help to push for solutions for obvious problems.

To want to do something and to make something happen, are two different kinds of shoes. If you outsourcing project does not cater for both parts, the ramp-up will be difficult.

One key element is to develop trust in your partner. The company needs to trust the supplier, that it has the capabilities and competencies to execute the process. The supplier needs to trust the new customer, that all information is provided.

Summary

While outsourcing a manufacturing process sounds simple, there are many problems along the road to success. Clearly identifying the advantages and transferring production steps effectively to a new supplier are not standard competencies of most corporate managers. Missing documentation and unclear expectations maybe the biggest problems at the beginning, but a lack of trust between the company and the outsourcing provider is the start, when the partnership deteriorates. Long-term relationships can lead to advantages for both partners but require a lot of communication between the partners.

Bibliography

Lee, H. L., & Schmidt, G. (2017). Using value chains to enhance innovation. Production and Operations Management, 26(4), 617–632.

Martel, A., & Klibi, W. (2016). Supply Chain Partnerships. In A. Martel & W. Klibi (Eds.), Designing Value-Creating Supply Chain Networks (pp. 207–242). Springer International Publishing. https://doi.org/10.1007/978-3-319-28146-9_6

Power, M., Bonifazi, C., & Desouza, K. C. (2004). The ten outsourcing traps to avoid. Journal of Business Strategy, 25(2), 37–42. https://doi.org/10.1108/02756660410525399

Scott, C., Lundgren, H., & Thompson, P. (2018). Guide to Outsourcing in Supply Chain Management. In C. Scott, H. Lundgren, & P. Thompson (Eds.), Guide to Supply Chain Management: An End to End Perspective (pp. 189–202). Springer International Publishing. https://doi.org/10.1007/978-3-319-77185-4_11

van Liemt, G. (n.d.). Subcontracting in electronics: From contract manufacturers to providers of Electronic Manufacturing Services (EMS). 36.

Wu, B., & Ellis, R. (2000). Manufacturing strategy analysis and manufacturing information system design: Process and application. International Journal of Production Economics, 65(1), 55–72. https://doi.org/10.1016/S0925-5273(99)00090-0