Whitepaper: How to drive Continuous Improvement in Supply Chain and Operations

Organizations and Industries are ultimately attempting to fully optimize their supply chains by centering on enhancing the efficiency of their supply chain operational processes. Efforts to improve effectiveness would result in a reduction in operational expenses, time, human capital, and elements of production. A company's supply chain is a key operational process that is required for achieving customer satisfaction.

A strong supply chain allows for maximum business process integration, efficiency, and responsiveness, ensuring that customers get whatever they want, at the time and place they desire. Due to the Continuous Improvement Processes (CIP) that established a realistic route for the Supply Chain Organization (SCO), a supply chain could become highly optimized by using one of the supportive tangibles and intangibles of CIP models such as Theory of Constraints (ToC), Six Sigma, and Lean.

Organizations need to drive CIP in their supply chain and operations, allowing them to increase cash flows, better order processing and shipping times, reduce costs, improve stock management, introduce greater transparency, and enhance customer satisfaction. CIP becomes necessary for supply chains and operations to adapt to ongoing changes, rapid technological innovation, increased demands, growing consumer standards, and uncertain industry trends.

Continuous Improvement Processes and its role in Supply Chain Management

“The supply chain stuff is really tricky.”- (Musk, 2017)

As per the definition of Supply Chain Council (SCC) Supply Chain Management (SCM) is “the integrated process of plan, source, make, deliver, and return spanning from the supplier´s supplier to the customer´s customer” (Husby & Swartwood, 2009). Hence, the supply chain encompasses all the operational activities of a business internally, as well as multiple partners and entities externally. Therefore, supply chain cannot act as a sole entity, it relies on its suppliers upstream, and needs to perpetually intensify the degree of its customer satisfaction downstream (Plenert, 2011).

“Nowhere does poor service lead directly to less sales revenue than in consumer goods and retail. The supply chain can make or break your competitive edge.”- ( 4FLOW, n.d.)

Thereby, this approach needs to be applied on a continuous basis in order to cope with the given challenges, market dynamics and increased customer expectations. These tactics need to be implemented to the highest possible level to build strong relationships with customers for long term retention, but also to reach optimum levels of supply chain efficiency and create a competitive edge for the company. According to Plenert, 2011 and Schniederjans et. al 2018, it is not sufficient to develop, integrate and rely on well-defined strategies and tactics, rather companies need to implement the concept of “Continuous Improvement Processes”.

The CIP mechanism needs to be assimilated as the business culture, which facilitates the improvement of processes at each operational sequence and activity (Plenert, 2011). To achieve the desired degree of efficiency, each CIP step needs to be applied and checked per Ross, Weston, & W, 2010. Further, to add value to the supply chain and optimize it, CIP needs to be reevaluated constantly with all parties involved.

Driving Continuous Improvement Process through applicable methods

Continuous Improvement Process (CIP) is an ongoing venture to elevate functions and processes throughout the supply chain. These attempts should aim for "gradual" development over time and are barely "one-time" breakthroughs. The goal of process improvement is to reduce inefficiencies or weak points in operations at each entity. The organizations may be facilitated by minimizing the time it takes for a procedure to be completed, enhancing process efficiency and improving the quality of the supply chain. These improvements are based on small progress, tweaks and basic changes, and not massive innovations or breakthroughs. In most cases, these incremental improvements are inexpensive and easy to implement (Steffes, n.d.).

CIPs are essential for supply chains to adapt and cope with continuous changes, further technological development, meet higher demand and consumer standards, and deal with uncertain market dynamics. In this context, continuous feedback is an integral part of Continuous Improvement(CI) by constantly attempting to identify opportunities for improvement by successfully evaluating and prioritizing the development of concepts and ideas (Meyer, 2019). Sankar, 2019 points out that there are four generally acknowledged theories or elementary keys that can be categorized as applicable methods in Continuous Improvement, namely: Lean CI, Six Sigma, Theory of Constraints (ToC) and, Dashboards. All these applicable methods could be a route or path towards optimization throughout the supply chain.

Lean CI

Lean CI is a technique for identifying opportunities for streamlining work, minimizing waste and, enhancing productivity. The more complex these operations become, the better the opportunity for inefficiencies to be set into motions. These inefficiencies can be classified into waste of time, increase in costs, and exertions in labor, negatively affecting cost of supply chain and operating income. Hence, Lean CI reduces these inefficiencies and directly involves diminishing waste and improving specific processes (Raza, 2021).

Lean Setup is always geared towards increasing customer benefits, reducing waste, and optimizing plant operations. Apart from waste reduction and process improvement, lean is also about building a culture of CI, wherein employees look for ways to improve their jobs and share plans, goals and proposals for CI in the supply chain (Michigan Technological University, 2019). Lean has been around since decades and its application in supply chain and operations still remains relevant today. The advantages of Lean CI are more efficient processes, shorter delivery cycles, decreased error rates, better quality, reduced costs of operations, strengthening in innovation, and enhancement of consumer experience (Raza, 2021).

Adopting best practice workflows and standard processes can help deploy the core concept of lean improvement that revolves around meeting consumer expectations through process improvement. The process, which reduces waste while using limited resources, drives accountability and pushes for CI in the supply chain. Lean is not a short-term arrangement but rather a long-term concept that needs investment of discipline, resources, effort, skills and knowledge.

Six Sigma

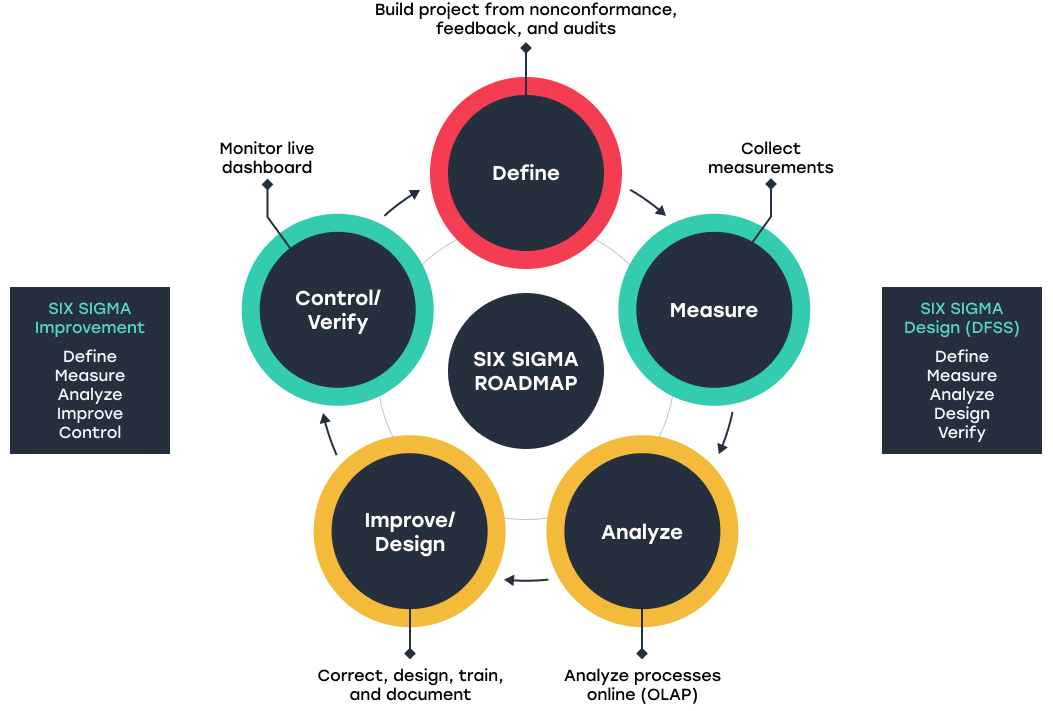

Six Sigma CI pivots on minimizing variability in the supply chain and providing a high degree of certainty. The objective of the six-sigma model is to attain foreseeable process outcomes through measurable procedures and operations with dedication to durable and lasting quality improvement (ASQ, 2020).

The six-sigma CI model is driven by data and is dependent on the company's internal staff infrastructure of experts trained in these methods to implement this model. Therefore, Six-Sigma is a set of tools and techniques designed to solve inefficiency issues and challenges throughout the supply chain. These techniques entail identifying and removing all the flaws that are clogging supply chain processes and preventing them from running as effectively and smoothly as possible (Industry standard for Six Sigma).

A further fundamental part of the Six Sigma model is the DMAIC (Define, Measure, Analyze, Improve and Control). Each component of Six Sigma DMAIC is explained by Terry (2019):

D: define the project objectives

M: measure processes to calculate the current performance

A: analyze to ascertain the core of the causes of flaws

I: improve the process by hindering and eliminating any flaws or issues and

C: control upcoming procedure performances to not cause any degrading or declining of process performances.

The six-sigma solution consist of data collection, analysis, and program management softwares. They reduce the amount of time needed for data collection and information gathering. The benefits of the six-sigma model are maximizing efficiency, amplifying accuracy, increasing customer service, and improving cash flow (Checkify, 2021). There are also seven basic quality tools- histograms, flowcharts, scatter plots, control charts, pareto charts, and cause and effect charts.

Theory of Constraints

The Theory of Constraints (TOC) is based on the idea that a constraint restricts the outcome of any process. Hence, the use of ToC assists companies in order to manage the project or process by utilizing five steps. Those steps include (1) identifying the constraints in a system, (2) exploiting the constraints, (3) subordinating, (4) elevating the constraints and (5) avoiding inertia if process failed (ToC | Lean Production, 2019).

In the same context, ‘constraint' refers to a significant barrier that prevents a company from reaching its maximum potential. Identifying and managing a constraint may be the best way to improve workflows and add value to the entire chain. It should noted that constraints can be internal as well as external limitations- the ToC approaches improves performance in a scientific manner. It is hypothesized that every comprehensive framework, including manufacturing processes, is made up into various interconnected activities, one of which acts as a constraint on the overall integrated structure (Pauchard, 2019).

“Every process has a constraint (bottleneck) and focusing improvement efforts on that constraint is the fastest and most effective path to improved profitability.” (ToC | Lean Production, 2019) Since firms' objective is to maintain profitability under short and long terms, the ToC offers a set of tools that aim to aid in the accomplishment of this goal. These tools are made up of the five steps mentioned above, accounting for an approach of assessing outcomes and decisions made by the management, and subsequently, the processes that should be implemented. A workflows collaboration platform powered by automation can help in executing the five ToC steps, especially for driving repeatable processes.

Dashboards

A performance dashboard is a tool for measuring performance and providing feedback for CI within an organization. It refers to a planning tool with a visual interface that showcases performance metrics. Further, it aids in focusing one’s team on achieving goals and generating ideas for enhancements.

"You cannot improve what you don’t measure.’’- (Stellman, 1998)

A performance dashboard is based on two fundamental management axioms, namely ‘’what gets measured gets done’’ and ‘’you cannot improve what you don’t measure’’ (Stellman, 1998). Consequently, a strong performance dashboard will show key performance indicators (KPI), goals, outcomes and the shortfall between goals and outcomes. Thus, data is used to assess the impact of day-to-day activities and to support informed, cooperative, and straightforward evaluation to enhance performance.

The performance dashboard model reports on the following evaluative and analytic parameters- control of production, product shift downtimes, quality and manufacturing rate of products, and causes of downtime. The CI dashboards allow quality improvements by enabling project supervisors to make data-driven decisions on systems to continue, get visibility on projects that are active at a given time, and better understand resource utilization. A dashboard expedites procedures to identify problems, improve efficiency, enhance data clarification, making information digestible and available for everybody. A supply chain dashboard aids in the consolidation of different databases while delivering more detailed results, resulting in better decision-making functionalities (Lachance, 2020).

Comparison of the Theories

Models: | Lean | Theory of Constraints | Six-Sigma |

Origin: | The quality evolution in Japan and Toyota | Novel ‘’The Goal’’ 1984 | Quality evolution in Japan |

Core of models: | Reduction of waste | Constraint’s control and management | Reduction of variation |

Focus of model: | Focused on the flow | Constraint systems | Focused on issues |

Primary effect: | Reduction of lead time | Profit increase | Money saving |

Application steps of models: |

|

|

|

Tools: |

|

|

|

Strength: |

|

|

|

Weakness: |

|

|

|

Achieve SCO with CIP

Organizations are endeavoring to optimize their supply chains by all means and invest greater efforts to reach the optimum level, whereby the core focus is on efficiency and effectiveness, and its equilibrium. However, per Cecere, 2014 & Mouzas, 2006, organizations have the tendency to put their emphasis on efficiency, while omitting effectiveness. In this context, Rosenfeld, (2013) asserts that “any attempt to improve efficiency, without an equal emphasis on effectiveness, is likely to be counterproductive” Organizations focus on efficiency gains by cutting their operational costs, human capital, and resource inputs. Yet, according to Cooper, et. al., 1997, these organizations neglect partly or wholly to be effective, in terms of differentiation, goal-attainment and fulfillment of customer needs.

“Any attempt to improve efficiency, without an equal emphasis on effectiveness, is likely to be counterproductive.” - Rosenfeld, (2013)

To achieve the efficiency and effectiveness equilibrium in a supply chain network, SCO can leverage technology such as blockchain, AI, and IoT. The supply chain of a company is a core operational process that is essential for positive customer satisfaction. Thus, a high-performing supply chain allows business efficiency and responsiveness, ensuring customer satisfaction, while also contributing to supply chain´s sustainable growth in the long-term and a safe manner (Dalin-Kaptzan, 2021). The prime goal of SCO is to ensure that production and assembly supply chain runs as efficiently as possible. This includes optimized inventory layout within the supply chain, as well as minimizing operational expenses such as production costs, cost of transportation, distribution costs, etc. By using CI processes throughout the supply chain, SCO would be achieved (Meyer, 2019).

By utilizing the four applicable CI methods supply chain profits and revenue increases which is the key value of the lean improvement model. Benefits from implementing CI include faster shipping and order fulfillment due to actionable information from dashboards, inventory optimization as a result of diminution of excess inventory, increase in transparency from use of software, and an increase in customer delight. By using one of the said CI processes models a supply chain can become fully optimized due to the CIP models that sets a clear path for the SCO (Dalin-Kaptzan, 2021).

Conclusion

The main purpose of an organization is not solely to ensure top-line growth, but to survive the competition and hostile market conditions in the long-term by keeping the customer-base satisfied and fulfilled. This approach, however, can only be achieved by controlling and managing the entire supply chain, be it internally or externally. The pre-requirement SCO is to increase efficiency and effectiveness to the same degree, whereby different types of methods such as lean, ToC, Six Sigma, Dashboard, etc. can facilitate and enhance its implementation.

When companies do implement these said methods, they can reduce costs, increase profits, reduce time, ease inventory, eliminate waste, and increase customer satisfaction. If organizations want to stay relevant, maintain market share, and competitive advantage, it is vital that they endorse for extensive use of the CIPs throughout their supply chain to ensure that their prospective frame of references is logical, adjustable, and resilient towards the uncertain markets, informed customers, and technological advancement.

Bibliography

Musk, E. (2017, 11 28). We can improve your supply chain risk monitoring . (R. Potter, Interviewer)

Husby, P., & Swartwood, D. (2009). Fix Your Supply Chain. Taylor & Francis Group, LLC.

Meyer, D. J.-U. (2019). Continuous Improvmnet Process | Innolytics Innovation. Retrieved from Innolytics Innovation: https://innolytics-innovation.com/continuous-improvement-process/

Raza, A. (2021). Lean Continuous Improvmnet - 2020's Best Guide. Retrieved from ThroughPut: https://throughput.world/blog/topic/lean-continuous-improvement/

Lachance, E. A. (2020). Real Rime Analytics Dashboard for the Continuous Improvment Process. Retrieved from blog.worximity.com: https://blog.worximity.com/en/industry-4_0/continuous-improvement-practitioner

Plenert, G. (2011). Strategic Continuous Process Improvement . McGraw Hill Professional.

Schniederjans, M., Schniederjans, D., Cao, R., & Gu, V. (2018). Topics In Lean Supply Chain Management. World Scientific Publication Co. Pte. Ltd.

Ross, D. F., Weston, F., & W, S. (2010). Introduction to Supply Chain Management Technologies. CRC Press.

Terry, K. (2019, 1 16). What Is DMAIC? | iSixSigma. Retrieved from iSigSigma: https://www.isixsigma.com/new-to-six-sigma/dmaic/what-dmaic/

ASQ. (2020). Six Sigma Definition. Retrieved from Asq.org: https://asq.org/quality-resources/six-sigma

Pauchard, E. (2019, 3 14). Theory of Constraints - Target process optimization. Retrieved from Aim for operational exellence!: https://www.coresilium.com/en/2019/03/the-theory-of-constraints/

Dalin-Kaptzan, Z. (2021). Supply Chain Optimization: Everything You Need to Know. Retrieved from Bringg: https://www.bringg.com/blog/logistics/supply-chain-optimization/

Cecere, L. (2014, 03 10). Forbes. Retrieved from The Most Efficient Supply Chain Is Not the Most Effective : https://www.forbes.com/sites/loracecere/2014/03/10/the-most-efficient-supply-chain-is-not-the-most-effective/?sh=50d8d8216c7a

Mouzas, S. (2006). Efficiency versus effectiveness in business networks. Journal of Business Research, 1124-1132.

4FLOW. (n.d.). Retrieved from Consumer goods and retail : https://www.4flow.com/industries-references/consumer-goods-and-retail.html

Gunasekarana, Patel, & McGaugheyc. (2004). A framework for supply chain performance measurement. International Journal of Production Economics, 333-347.

Sankar, R. (2019, 10 31). StackPath. Retrieved from Five Ways to Optimize Supply Chain Management : https://www.industryweek.com/supply-chain/planning-forecasting/article/21958271/five-ways-to-optimize-supply-chain-management

Michigan Technological University. (2019). Michigan Technological University. Retrieved from What is Lean: https://www.mtu.edu/improvement/learn/what/

SixSigma. (2017, 2 21). Understanding the Basics - Lean Process Improvment. Retrieved from SixSigma.us: https://www.6sigma.us/six-sigma-articles/understanding-basics-lean-process-improvement/

Steffes, B. (n.d.). How to start a continuous improvement program: 6 simple steps. Retrieved from resources.cayote.com: https://resources.coyote.com/source/continuous-improvement

ToC | Lean Production. (2019). ToC | lean production. Retrieved from www.leanproduction.com: https://www.leanproduction.com/theory-of-constraints/

Stellman, J. M. (1998). Encyclopaedia of Occupational Health and Saftey. Geneve: International Labour Office.

Industry standard for Six Sigma. (2019). Six Sigma Definition, What is Six Sigma Mthodology. Retrieved from The Council for Six Sigma Certification: https://www.sixsigmacouncil.org/six-sigma-definition/

Cooper, M., Lambert, D., & Pagh, J. (1997). Supply Chain Management: More Than a New Name for Logistics. emerald-inside, 1-14.

Checkify. (2021). Six Sigma CIP Checkify. Retrieved from Checkify: https://checkify.com/blog/six-sigma-continuous-process-improvement/

Geodis. (2021, 01 07). Supply Chain Optimization. Retrieved from GEODIS: https://geodis.com/activity/supply-chain-optimization